Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving landscape of kitchen appliances, one product has quietly surged to the forefront, transforming the way we cook and eat. The air fryer, once a niche gadget, has become a staple in modern kitchens, offering a healthier alternative to traditional frying methods. This shift has been fueled by not just innovation but also by the demand for comprehensive solutions that ensure safety and compliance. In this article, we delve into the importance of turnkey solutions in the OEM process, the significance of UL certification, the latest innovations in air fryer design, and the future trends shaping this dynamic market.

The air fryer market has experienced a remarkable surge in popularity over recent years, becoming a staple in the kitchen appliances landscape. With health and convenience at the forefront of consumer priorities, air fryers have stepped into the spotlight as a versatile and innovative solution for cooking with less oil. This segment has seen a proliferation of brands, models, and features, catering to a diverse range of cooking styles and preferences.

The appeal of air fryers lies in their ability to mimic the crispy texture of deep-fried foods while reducing the fat content significantly. This health-conscious approach has resonated with a broad audience, from fitness enthusiasts to families looking for quicker and healthier meal options. The compact size of these appliances makes them perfect for countertop cooking, adding a touch of convenience to daily life.

As the market has matured, there’s been a shift towards not just the availability of air fryers but also the quality and sophistication of these devices. Consumers are now seeking not just functionality but also durability, smart features, and eco-friendly designs. This evolution has created a fertile ground for original equipment manufacturers (OEMs) to innovate and differentiate their products in a highly competitive landscape.

In this dynamic environment, the concept of turnkey solutions has become increasingly important for OEMs. These comprehensive services encompass design, engineering, production, and certification, ensuring that the end product is not just of high quality but also ready to enter the market with minimal hassle. The demand for turnkey solutions has been fueled by the need for speed to market and the complexity of navigating various regulatory standards, particularly for safety and compliance.

The market for air fryers is global, with Europe and North America leading the way in terms of adoption and sales. This has attracted a host of manufacturers, from established kitchen appliance companies to new entrants looking to capitalize on the trend. However, what sets some brands apart from the rest is their commitment to quality, innovation, and adherence to rigorous safety standards.

In the heart of this competitive industry, the role of UL (Underwriters Laboratories) certification cannot be overstated. UL is a respected independent safety science company that provides testing and certification services for a wide range of products. For air fryer OEMs, achieving UL certification is a critical step that ensures their products meet the highest safety standards, which is essential for consumer trust and market acceptance.

The process of obtaining UL certification involves a thorough evaluation of the air fryer’s design, materials, construction, and electrical safety. This includes testing for overheating, fire resistance, electrical shock protection, and other safety aspects. The certification not only provides peace of mind to consumers but also gives OEMs a competitive edge in a market where safety is a top priority.

Innovation in air fryer technology continues to push boundaries, with advancements such as variable temperature control, preset cooking programs, and even wireless connectivity. These features not only enhance the user experience but also open up new possibilities for product development. For OEMs, staying ahead in this fast-paced market means constantly exploring new materials, components, and manufacturing techniques.

Moreover, the demand for customizability is on the rise, with consumers expecting products that can be tailored to their specific needs and preferences. This trend has led to a surge in the customization of air fryers, with various sizes, color options, and specialized features being developed to cater to niche markets.

In conclusion, the air fryer market is a vibrant and rapidly evolving sector within the kitchen appliances industry. It is characterized by a high level of competition, driven by the quest for innovation and adherence to safety standards. As OEMs continue to refine their turnkey solutions and secure certifications like UL, they are not only ensuring product safety but also setting themselves apart in a market that values both quality and creativity.

The air fryer market has experienced a remarkable surge in popularity over recent years, transforming the landscape of kitchen appliances. Once a niche product, these innovative cooking devices have now become a staple in many homes around the world. This shift can be attributed to several key factors that have propelled air fryers into the forefront of culinary innovation.

Once confined to gourmet kitchens and specialty shops, air fryers have now found their way into the mainstream. Their compact size and ease of use have made them a favorite among busy individuals and families looking to enjoy healthier, crispy fried foods without the guilt. The allure of these appliances lies in their ability to mimic the taste and texture of deep-fried foods while significantly reducing the amount of oil needed, thus lowering the calorie count and improving health outcomes.

The convenience factor cannot be overstated. Air fryers are designed to simplify the cooking process, allowing users to prepare a variety of dishes with minimal effort. From golden-brown French fries to crispy chicken wings, these appliances can handle a wide range of recipes, making them versatile companions in the kitchen. Their ability to cook a variety of foods at once also saves time, as multiple ingredients can be air-fried simultaneously.

Moreover, the technology behind air fryers has evolved significantly. Modern units are equipped with precise temperature controls and timers, ensuring that food is cooked to perfection. These advancements have not only improved the quality of the final product but have also made air fryers safer to use, as they prevent the risk of oil fires associated with traditional deep-frying methods.

As consumers become more health-conscious, the demand for air fryers has skyrocketed. The reduction in oil usage is a direct response to the growing interest in heart-healthy cooking methods. Air fryers offer a guilt-free alternative to deep-frying, allowing people to enjoy their favorite fried foods while maintaining a balanced diet.

The environmental impact of cooking methods has also played a role in the rise of air fryers. With concerns over food waste and the sustainability of cooking oils, air fryers present a more eco-friendly option. They require less oil, which can be reused multiple times, and they also tend to use less energy than traditional ovens or fryers.

The integration of smart technology has further propelled the popularity of air fryers. Many models now come with features like Bluetooth connectivity, allowing users to control their appliances remotely via their smartphones. This added convenience has made air fryers even more appealing to tech-savvy consumers who appreciate the seamless integration of kitchen appliances into their digital lives.

Retailers have also played a crucial role in the air fryer’s ascent. Supermarkets, home goods stores, and online marketplaces have featured these appliances prominently, making them easily accessible to a broad audience. The marketing of air fryers as a “healthy frying” solution has resonated with consumers, who are increasingly seeking healthier alternatives to traditional cooking methods.

The rise of air fryers has not been without its challenges. The market has seen a proliferation of brands and models, which can make it difficult for consumers to choose the right appliance for their needs. However, this competition has also driven innovation, with manufacturers constantly seeking to outdo each other in terms of design, functionality, and health benefits.

As the air fryer market continues to grow, manufacturers are exploring new ways to expand their product lines. We’ve seen the emergence of air fryer ovens, which combine the features of an air fryer with those of a conventional oven, allowing for a wider range of cooking options. The future of air fryers may also include more personalized settings and health tracking capabilities, further solidifying their position as a must-have kitchen appliance.

In conclusion, the rise of air fryers as a game-changer in kitchen appliances is a testament to the power of innovation, consumer demand, and environmental consciousness. As technology continues to advance and health trends evolve, air fryers are poised to remain a staple in modern kitchens, offering a healthier, more convenient, and sustainable way to enjoy fried foods.

In the ever-evolving landscape of the kitchen appliances industry, the rise of turnkey solutions has become a cornerstone for Original Equipment Manufacturers (OEMs) looking to streamline their operations and enhance their offerings. Turnkey solutions are comprehensive packages that include design, engineering, manufacturing, quality control, and after-sales support, essentially providing OEMs with a complete product from start to finish. This approach is not just a trend; it’s a game-changer that offers several crucial advantages.

The first and most apparent benefit is the efficiency it brings to the OEM process. Traditionally, OEMs had to manage multiple suppliers and vendors for different aspects of their product development. This fragmentation often led to delays, miscommunication, and a lack of consistency in the final product. With a turnkey solution, all these components are sourced and managed by a single provider, ensuring a seamless and timely production process.

This streamlined process also translates to cost savings. By eliminating the need to negotiate with various suppliers, OEMs can negotiate better terms with a single vendor, often securing bulk discounts and favorable pricing. Additionally, the reduced complexity of the supply chain means lower administrative costs and a more predictable budget.

Quality control is another area where turnkey solutions shine. When a manufacturer offers a turnkey solution, they take full responsibility for the quality of every component that goes into the final product. This means that OEMs can trust that the air fryers they are producing will meet the highest standards, without the risk of receiving subpar parts from external suppliers. Consistent quality is crucial in maintaining brand reputation and customer satisfaction.

Turnkey solutions also allow for rapid prototyping and customization. In a market as dynamic as kitchen appliances, the ability to quickly adapt to new trends and customer demands is invaluable. A turnkey provider can offer quick turnaround times for design changes and can even help OEMs create entirely new products from the ground up. This agility is essential for staying competitive and meeting the ever-changing needs of consumers.

Moreover, turnkey solutions often come with a wealth of expertise and experience. These providers have been in the industry for years, if not decades, and have a deep understanding of what works and what doesn’t. This knowledge can be invaluable to OEMs, especially those entering new markets or looking to expand their product lines. The turnkey provider can act as a strategic partner, offering insights and advice that can lead to innovative and successful products.

In the case of air fryers, which have seen a surge in popularity due to their health benefits and convenience, turnkey solutions are particularly beneficial. The technology behind air frying is complex, requiring precise engineering to ensure that the appliance cooks food evenly and efficiently. A turnkey provider can handle the intricate details of the design and manufacturing process, ensuring that the air fryer is not only functional but also safe and user-friendly.

Another important aspect of turnkey solutions is the integration of sustainable practices. As consumers become more environmentally conscious, OEMs are under pressure to produce appliances that are eco-friendly. Turnkey providers often incorporate sustainable materials and manufacturing processes into their offerings, making it easier for OEMs to meet these demands without having to research and implement these practices themselves.

Lastly, turnkey solutions offer peace of mind. For OEMs, the prospect of managing a complex supply chain and ensuring quality across all components can be daunting. With a turnkey provider, this responsibility is taken off their hands, allowing them to focus on their core competencies and strategic growth initiatives.

In conclusion, the importance of turnkey solutions in the OEM process cannot be overstated. They offer efficiency, cost savings, quality control, rapid prototyping, expertise, sustainability, and peace of mind. For OEMs looking to enter or excel in the kitchen appliances market, especially with products like air fryers, partnering with a turnkey provider is a strategic move that can lead to a competitive edge and long-term success.

In today’s highly competitive kitchen appliances market, ensuring that your products meet the strictest safety standards is paramount. This is where UL certification comes into play, acting as a vital gateway for products to enter new markets. Understanding the significance of this certification can make all the difference in the success of your Original Equipment Manufacturer (OEM) business.

The cornerstone of UL certification lies in its rigorous testing and evaluation process. As a globally recognized mark of safety, quality, and performance, UL (Underwriters Laboratories) has been setting industry standards for more than a century. For OEMs looking to establish a strong presence in the market, achieving UL certification is not just a checkbox but a critical step towards building consumer trust.

One of the primary reasons UL certification is so crucial is its impact on consumer confidence. With countless kitchen appliances flooding the market, consumers are often wary of purchasing products that haven’t been thoroughly vetted for safety. The UL mark is a reassurance that the product has undergone extensive testing to ensure it meets or exceeds safety standards, reducing the risk of fire, electrical shock, and other hazards.

Moreover, UL certification is often a regulatory requirement in many countries, especially in the United States and Canada. For OEMs targeting these markets, not having the UL certification can be a barrier to entry. Distributors and retailers are increasingly looking for products that have this certification as it simplifies their compliance process and reduces their legal risks.

The certification process itself is meticulous. It involves thorough examination of the product’s design, materials, and manufacturing process. UL inspectors verify that the appliance meets specific safety criteria, including electrical, thermal, mechanical, and chemical aspects. This ensures that the air fryer, for instance, operates efficiently without posing a risk to users.

Beyond safety, UL certification also encompasses performance standards. The certification process tests the air fryer’s ability to consistently deliver the desired cooking results, maintaining food quality and texture. This aspect is particularly important for OEMs that aim to offer premium products, as it guarantees that their customers receive a reliable and consistent experience every time they use the appliance.

For OEMs, the process of obtaining UL certification can be complex and time-consuming. It requires a deep understanding of the certification process and the ability to navigate the technical requirements. This is where turnkey solutions become invaluable. A turnkey provider can offer a comprehensive package that includes not only the certification itself but also guidance on design, manufacturing, and compliance.

Turnkey solutions streamline the certification process by handling all the necessary tasks. They work closely with OEMs to ensure that every aspect of the product is in line with UL standards. This can include modifying the design, sourcing compliant materials, or adjusting manufacturing processes. By doing so, turnkey providers save OEMs time and resources, allowing them to focus on their core competencies.

Furthermore, turnkey solutions often include ongoing support. This is particularly beneficial as safety standards and regulations can change over time. With a turnkey partner, OEMs can stay up-to-date with the latest requirements and maintain their certification status without interruption.

Another key advantage of turnkey solutions is the ability to offer a wide range of services. This can include market research, product design, engineering, quality control, and after-sales support. By having all these services under one roof, OEMs can ensure a seamless transition from product development to market launch.

In conclusion, UL certification is not just a regulatory requirement; it’s a symbol of quality and safety that consumers look for. For OEMs, the journey to obtain this certification can be daunting, but with the right turnkey solution, it becomes a manageable and efficient process. By partnering with a provider that understands the intricacies of UL certification, OEMs can ensure that their products are not only compliant with safety standards but also competitive in the global market.

In recent years, the air fryer has transformed the culinary landscape, becoming a staple in kitchens around the globe. This sleek and efficient kitchen appliance has not only gained popularity for its ability to mimic deep-frying with minimal oil but also for its innovative design and features that enhance cooking experiences. Let’s delve into the latest advancements in air fryer design and features that are redefining the market.

The air fryer’s fan technology is at the heart of its functionality, and manufacturers have been fine-tuning this aspect to achieve better cooking results. Newer models now come with variable speed fan settings, allowing users to control the air flow and adjust the cooking temperature for different types of foods. This precision is crucial for achieving that perfect crispiness on the outside while keeping the inside tender and juicy.

One of the most notable innovations is the introduction of multi-layered cooking baskets. These baskets, which can stack two or more layers, maximize the cooking capacity of the air fryer while maintaining even heat distribution. This feature is especially appealing to families and those who enjoy entertaining, as it allows for batch cooking without the need for multiple appliances.

Another design improvement is the inclusion of non-stick surfaces that are not only easy to clean but also durable. The use of high-quality, PFOA-free materials ensures that the interior of the air fryer remains scratch-resistant and free from harmful chemicals, providing peace of mind for health-conscious consumers.

Smart technology has also made its way into air fryer design. Modern models are now equipped with digital displays and touchscreens that offer a range of pre-programmed settings for different types of meals. Users can choose from a variety of cooking modes, including “fry,” “roast,” “bake,” and “grill,” with the touch of a button. This not only simplifies the cooking process but also ensures that users achieve the desired results without guesswork.

One feature that has garnered significant attention is the inclusion of a “preheat” function. This allows the air fryer to reach the optimal cooking temperature before the food is added, ensuring that the cooking process starts quickly and efficiently. The preheat feature is particularly beneficial for those who want to prepare a meal in a hurry.

For those who prefer hands-off cooking, air fryers with automatic shut-off and safety locks are becoming increasingly common. These features prevent overcooking and potential fires, adding an extra layer of safety to the appliance. Additionally, some models now offer “keep warm” functions, which maintain the temperature of cooked food until it’s ready to be served.

The design of the air fryer has also evolved to be more user-friendly. Many newer models feature ergonomic handles and compact sizes that make them easier to store and transport. The inclusion of storage containers within the unit itself is another convenience that saves counter space and encourages batch cooking.

In terms of features, air fryers are now coming with a variety of attachments and accessories. These include pizza stones, rotisserie forks, and skewers, which expand the versatility of the appliance beyond just frying. Users can now enjoy a broader range of cooking techniques and recipes with the same appliance.

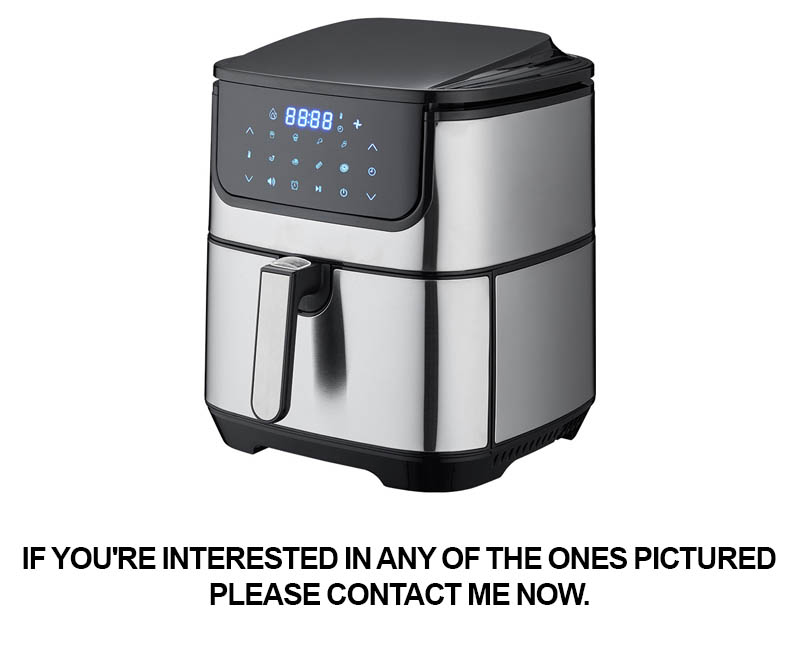

Lastly, the aesthetics of air fryers have improved as well. From sleek stainless steel finishes to colorful, modern designs, these appliances are not just functional but also serve as a stylish addition to any kitchen. The ability to match the air fryer with the existing kitchen decor has made it a sought-after item for many consumers.

In conclusion, the air fryer market is continuously evolving with innovative design and features that cater to the needs and desires of consumers. From technological advancements to user-friendly innovations, the air fryer has become more than just an appliance; it’s a versatile tool that enhances the cooking experience and adds convenience to daily life.

In the bustling world of kitchen appliances, the air fryer has emerged as a revolutionary player, offering a healthier alternative to traditional deep-frying. Choosing a Turnkey UL Certified Air Fryer OEM can be a game-changer for brands looking to capitalize on this trend. Here’s why.

Streamlined Production ProcessWhen you opt for a Turnkey OEM, you’re not just buying a product; you’re investing in a complete production solution. This means from design to manufacturing, quality control, and certification, everything is taken care of by the OEM. It eliminates the complexities of sourcing components, managing production lines, and ensuring compliance with safety standards, allowing you to focus on your brand and marketing strategies.

Quality AssuranceThe “Turnkey” aspect of an OEM service often comes with a guarantee of quality. These manufacturers are committed to producing high-quality air fryers that meet or exceed industry standards. By adhering to strict quality control measures, they ensure that every unit that leaves their facility is not just functional but also safe, reliable, and durable. This peace of mind is invaluable in a market where customer satisfaction and trust are paramount.

UL Certification: The Gold StandardOne of the most significant benefits of partnering with a Turnkey UL Certified Air Fryer OEM is the inclusion of the prestigious Underwriters Laboratories (UL) certification. This certification is recognized globally as a symbol of safety and quality. It signifies that the air fryer has undergone rigorous testing and meets all necessary safety standards, including electrical, fire, and thermal safety. For consumers, this certification is a strong selling point, as it provides reassurance that the product they are purchasing is safe to use.

Cost-Effective ManufacturingManufacturing can be a costly endeavor, especially when you’re dealing with the complexities of safety certifications and quality control. A Turnkey UL Certified Air Fryer OEM can offer significant cost savings. They have the expertise and scale to negotiate better deals on materials, components, and production, which can translate into lower costs for you. This efficiency not only helps in maintaining competitive pricing but also allows for more investment in marketing and innovation.

Customization and BrandingOEMs often provide customization services, allowing you to brand the air fryer with your logo and design. This is particularly beneficial for businesses looking to create a unique market presence. By offering a product that stands out visually, you can differentiate your brand from competitors. Additionally, a custom design can cater to specific consumer preferences, which can be a crucial factor in attracting new customers.

Rapid Time-to-MarketIn the fast-paced consumer electronics market, speed is of the essence. A Turnkey OEM can help you reduce the time-to-market for your air fryer. They have the infrastructure and experience to quickly bring your product from concept to reality. This agility is crucial in capitalizing on market trends and staying ahead of the competition.

Technical Support and After-Sales ServiceA reputable Turnkey UL Certified Air Fryer OEM typically offers comprehensive technical support and after-sales service. This includes assistance with product design, troubleshooting, and maintenance. For your brand, this means fewer customer complaints and a more positive brand image. It also opens up opportunities for customer loyalty programs and repeat business.

Compliance with Global RegulationsNavigating the maze of international safety and regulatory standards can be daunting. A Turnkey OEM that provides UL certification ensures that your air fryer is compliant with not only UL standards but also with other global regulations. This makes it easier for you to market and sell your product across borders, reaching a wider audience.

Long-Term Strategic PartnershipsWhen you choose a Turnkey UL Certified Air Fryer OEM, you’re not just making a single transaction. You’re establishing a long-term strategic partnership. This can lead to collaborative innovation, where the OEM can provide insights and suggestions for new features and technologies, helping your brand to stay ahead of the curve.

**In conclusion, selecting a Turnkey UL Certified Air Fryer OEM brings a multitude of benefits, from streamlined production and cost savings to quality assurance and global market access. It’s a strategic move that can help your brand not only survive but thrive in the competitive kitchen appliance industry. By leveraging the expertise and resources of a Turnkey OEM, you’re not just entering the market with a product; you’re entering with a promise of safety, quality, and innovation that resonates with consumers worldwide.”

In the competitive landscape of kitchen appliances, turnkey OEMs have played a pivotal role in shaping the market for air fryers. Let’s delve into some case studies that showcase the success of air fryer products developed by these turnkey OEMs.

The Air Fryer Revolution: A Leap ForwardOne of the standout successes in the air fryer market is the introduction of a sleek, energy-efficient model by a renowned OEM. This product not only offered the convenience of air frying but also incorporated smart features that allowed for remote monitoring and control through a smartphone app. The turnkey OEM managed the entire process, from design to manufacturing, ensuring that the product was not only innovative but also met the stringent safety standards required for market entry.

Customization and Scalability: A Recipe for SuccessA smaller turnkey OEM worked closely with a mid-sized kitchen appliance brand to develop a line of air fryers tailored to the brand’s target market. By understanding the brand’s vision and the consumer’s needs, the OEM was able to create a range of air fryers that offered both advanced features and a competitive price point. This collaboration allowed the brand to scale up production quickly, meeting consumer demand without the complexities of in-house manufacturing.

Sustainability and Eco-Friendly DesignsA turnkey OEM specializing in sustainable products partnered with an eco-conscious company to develop an air fryer that used up to 75% less oil than traditional deep fryers. The design of the air fryer was not only energy-efficient but also included a durable, recyclable exterior. This project was a hit with environmentally conscious consumers and helped the partnering brand establish a strong market presence in the health and wellness segment.

Innovative Cooking Functions and AccessoriesAn innovative turnkey OEM collaborated with a global kitchen appliance brand to introduce an air fryer that went beyond traditional frying. The product featured a range of cooking modes, including roasting, grilling, and baking, and came with a variety of accessories to cater to different cooking styles. This comprehensive approach to the product allowed the brand to appeal to a broader audience, from busy professionals to gourmet cooks looking for a versatile kitchen appliance.

Global Expansion and LocalizationA turnkey OEM with a global footprint successfully launched a line of air fryers in multiple international markets. The OEM’s expertise in localization meant that the air fryers were adapted to local power standards, languages, and cooking preferences. This case study highlights the importance of understanding diverse markets and adapting products accordingly to ensure success on a global scale.

Quality Control and Customer SatisfactionA well-known turnkey OEM focused on quality control and customer satisfaction when developing air fryer products for a leading brand. The OEM’s rigorous testing protocols and focus on component quality led to a product with a low defect rate and high reliability. This attention to detail not only enhanced the brand’s reputation but also resulted in repeat purchases and positive word-of-mouth referrals.

E-commerce and Direct-to-Consumer StrategiesA turnkey OEM helped a new brand enter the market by developing a line of air fryers specifically designed for e-commerce sales. The product was optimized for online marketing, with clear, compelling visuals and detailed product descriptions. The OEM also ensured that the product packaging was user-friendly and eco-friendly, aligning with the brand’s commitment to sustainability. This strategy helped the brand achieve rapid growth and a strong online presence.

These case studies illustrate the diverse ways in which turnkey OEMs contribute to the success of air fryer products. From innovative design and features to market adaptation and quality control, the role of these OEMs is integral in bringing cutting-edge air fryers to consumers worldwide.

The air fryer market has seen a surge in popularity, transforming the way consumers cook and enjoy their meals. These compact appliances have become a staple in modern kitchens, offering a healthier alternative to traditional deep-frying. As the industry evolves, so do the innovations and features that air fryers boast. Let’s delve into the latest advancements in air fryer design and features.

Air fryers have traditionally been seen as a simple solution for cooking with minimal oil, but the latest models are far from basic. One of the most significant innovations is the inclusion of smart technology. Modern air fryers are now equipped with digital displays and programmable settings, allowing users to select the perfect cooking temperature and time for a wide range of foods. This not only simplifies the cooking process but also ensures consistent results every time.

The design of air fryers has also seen a transformation. Many newer models feature a sleek, modern aesthetic that complements contemporary kitchen decor. The compact size of these appliances makes them ideal for small kitchens or those with limited counter space. Moreover, many air fryers now come with detachable baskets, making it easier to clean and store the appliance.

One of the standout features in recent air fryer designs is the inclusion of a rotisserie function. This allows for the cooking of whole birds or larger cuts of meat, providing a healthier alternative to traditional roasting. The rotisserie function often includes a spit that rotates the food, ensuring even cooking and browning.

In terms of safety, air fryers have made significant strides. Modern models are equipped with overheat protection, auto shut-off features, and cool-touch handles to prevent accidents. These safety features are particularly important for households with children or those who may not be as vigilant about kitchen safety.

Another innovation that has gained traction is the inclusion of air fryer lids. These lids not only help to keep the heat contained during cooking but also serve as a space-saving feature when the appliance is not in use. Many lids are also designed to be leak-proof, making them ideal for cooking acidic foods like tomatoes without worrying about splatters.

The versatility of air fryers has expanded with the addition of multi-functional capabilities. Some models now include features like dehydrating, reheating, and even baking. This versatility means that air fryers can replace several kitchen appliances, saving space and reducing energy consumption.

The health benefits of air fryers are undeniable. They use hot air to circulate around the food, which reduces the need for oil by up to 80%. This not only makes air-fried foods lower in fat but also retains more of the food’s natural flavors and nutrients. As consumers become more health-conscious, the demand for air fryers with low-fat, low-calorie cooking options continues to grow.

In terms of technology, some air fryers are now equipped with Wi-Fi connectivity, allowing users to control their appliances remotely via smartphone apps. This feature enables users to start, monitor, and even end cooking sessions while they are away from the kitchen. It also provides a convenient way to keep track of cooking times and temperatures.

The market for air fryers is also seeing an increase in the use of eco-friendly materials. Many manufacturers are now using recycled plastics and sustainable materials in the construction of their appliances, aligning with the growing demand for environmentally conscious products.

As the air fryer market continues to grow, we can expect to see even more innovations. The integration of artificial intelligence and machine learning could lead to air fryers that learn your preferences and cooking habits, providing personalized cooking recommendations. Additionally, advancements in cooking technology may lead to air fryers that can adjust their cooking parameters based on the type of food being prepared.

In conclusion, the air fryer market is experiencing a renaissance, with manufacturers pushing the boundaries of what these appliances can do. From smart technology and multi-functional capabilities to health benefits and eco-friendly designs, the future of air fryers looks promising. As consumers seek out healthier, more efficient, and convenient cooking solutions, the air fryer is poised to remain a staple in modern kitchens for years to come.

The synergy between innovation and compliance has been a driving force behind the success of air fryer OEMs. As the market evolves, so do the products they develop, blending cutting-edge features with rigorous safety standards. This section delves into the future of air fryers, highlighting trends and predictions that are shaping the industry.

Air fryers have already transformed the way we think about cooking, offering a healthier alternative to traditional frying methods. As consumer awareness of health and wellness continues to grow, the demand for air fryers is expected to surge. One trend that is likely to emerge is the integration of smart technology, allowing users to control their appliances remotely and track their cooking progress through apps.

Predictions suggest that air fryers will become more energy-efficient, with advancements in insulation and motor technology. This will not only reduce the environmental footprint but also make air fryers more affordable and accessible to a wider audience. Additionally, we can anticipate a shift towards modular design, where users can customize their appliances by adding or removing components, such as different types of baskets or attachments for specific cooking tasks.

Another trend to watch for is the inclusion of health-centric features, such as non-stick coatings that are free from harmful chemicals or programmable settings that help users monitor and adjust their cooking times and temperatures for optimal health benefits. Brands that can innovate in this area are poised to capture the attention of health-conscious consumers.

The rise of eco-friendly materials is also a significant trend that is expected to influence the future of air fryers. As consumers become more environmentally conscious, manufacturers will be under pressure to produce air fryers that are made from sustainable and recyclable materials. This not only aligns with ethical consumer values but can also open up new markets in regions where environmental sustainability is a top priority.

The integration of AI and machine learning into air fryers is another prediction that could revolutionize the industry. Imagine an air fryer that learns from your cooking habits and suggests recipes or cooking times based on your preferences and the ingredients you have available. This level of personalization could elevate the air fryer from a kitchen appliance to a culinary companion.

In terms of compliance, the future will demand that air fryer OEMs adhere to stricter safety regulations and standards. As the technology advances, so does the need for rigorous testing and certification to ensure that air fryers are safe for consumers. This means that OEMs must stay abreast of global safety standards, such as those set by the Underwriters Laboratories (UL), to remain competitive in the market.

The intersection of innovation and compliance is where the true potential of air fryer OEMs lies. By pushing the boundaries of what is possible while maintaining the highest levels of safety and quality, these companies can create products that not only meet consumer expectations but also exceed them. This dual focus is what will define the future of air fryers and set industry leaders apart from followers.

In conclusion, the future of air fryers is bright, with a host of exciting trends and predictions on the horizon. From smart technology and modular design to health-centric features and eco-friendly materials, the next generation of air fryers will be more versatile, efficient, and user-friendly than ever before. As air fryer OEMs continue to innovate and comply with safety standards, they will not only satisfy consumer demands but also contribute to the broader trend of healthier, more sustainable living.