Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the bustling world of culinary innovation, the sandwich grill has emerged as a cornerstone of convenience and efficiency. As technology advances and consumer demands evolve, these compact kitchen marvels are not just cooking up a storm; they’re reshaping the way we think about fast food and casual dining. This article delves into the transformative journey of continuous operation sandwich grill plants, exploring their innovative designs, market trends, and the profound impact they have on efficiency and profitability.

The sandwich industry has seen a remarkable transformation over the years, and at the forefront of this evolution is the rise of continuous operation sandwich grill plants. These innovative facilities have become a game-changer, not just for sandwich manufacturers but for the entire foodservice sector. Here’s a closer look at how these plants have gained prominence and why they’re reshaping the industry.

With the fast-paced lifestyle of modern consumers, there’s a growing demand for quick and convenient meals. Sandwiches, with their versatility and ease of preparation, have become a staple in the quick-service restaurant (QSR) market. This demand has spurred the development of high-efficiency sandwich grill plants that operate continuously, ensuring a steady supply of freshly cooked sandwiches.

These plants are designed with efficiency in mind, employing advanced technology to maintain a seamless workflow. The continuous operation concept allows for around-the-clock production, reducing downtime and maximizing output. This is particularly beneficial for large-scale operations that require a consistent supply of sandwiches to meet peak demand hours.

The technology driving these continuous operation sandwich grill plants is nothing short of impressive. Automation and precision are key components, with machines that can grill, toast, and assemble sandwiches with incredible speed and accuracy. The use of smart sensors and programmable logic controllers (PLCs) ensures that each sandwich meets the exact specifications required for quality and consistency.

Moreover, these plants are designed for minimal waste. Advanced inventory management systems track ingredients in real-time, allowing for precise ordering and reducing the risk of overstocking. This not only cuts costs but also minimizes the environmental impact of food production.

The rise of these continuous operation sandwich grill plants has also been fueled by the increasing trend towards healthier eating. As consumers become more health-conscious, there’s a growing demand for sandwiches that are not only quick but also nutritious. These plants can easily adapt to cater to this trend by offering a variety of ingredients and customizable options.

In Europe and North America, where the sandwich market is already well-established, these plants have found a particularly receptive audience. The QSR landscape in these regions is highly competitive, and the ability to offer a high-quality product with consistent taste and appearance is a significant advantage.

One of the standout features of these continuous operation sandwich grill plants is their flexibility. They can produce a wide range of sandwich types, from classic ham and cheese to gourmet options with exotic fillings. This versatility allows manufacturers to cater to niche markets and seasonal trends, ensuring that they remain relevant and competitive.

Despite the numerous benefits, the transition to continuous operation sandwich grill plants isn’t without its challenges. The initial investment for such a setup is substantial, and the technology requires skilled operators to manage and maintain. However, the long-term cost savings and increased productivity make it a worthwhile investment for many businesses.

Another critical aspect is the integration of these plants into existing supply chains. Ensuring that ingredients are delivered on time and stored correctly is essential for the continuous operation to be successful. Collaborations with suppliers and logistics partners have become increasingly important to ensure a smooth and uninterrupted production process.

The success of continuous operation sandwich grill plants can be seen in the case studies of several leading manufacturers. These companies have not only increased their output but have also improved the quality of their products. The ability to produce sandwiches at scale without compromising on taste and freshness has been a game-changer for their business models.

Looking ahead, the future of sandwich grill technology looks promising. Innovations in automation and food safety are expected to further enhance the capabilities of these plants. Additionally, the integration of these technologies with digital platforms could lead to even greater efficiency and customer satisfaction.

In conclusion, the rise of continuous operation sandwich grill plants is a testament to the industry’s ability to adapt to changing consumer demands. As the sandwich market continues to grow, these plants are poised to play a pivotal role in shaping the future of fast food production.

The sandwich grill market in Europe and North America has undergone a remarkable transformation over the years, reflecting the ever-growing demand for fast, convenient, and delicious food options. This evolution has been marked by several key shifts that have reshaped the landscape of the industry.

Once primarily found in diners and fast-food joints, sandwich grills have now become a staple in a variety of venues, from high-end restaurants to casual cafes. The market has expanded with the rise of food trucks and the increasing popularity of street food culture, which has brought a new level of versatility to the traditional sandwich grill.

The introduction of new technologies has been a driving force behind the evolution. Early models were often simple, using direct heat to cook sandwiches, but today’s grills are equipped with advanced features like adjustable temperature controls, non-stick surfaces, and even programmable settings that cater to specific sandwich recipes. This technological advancement has not only improved the quality of the final product but has also made the grilling process more efficient for chefs.

As consumer preferences have shifted towards healthier eating habits, the sandwich grill market has responded by offering a wider range of options. This includes grills that can cook not just sandwiches but also wraps, paninis, and even vegetarian and vegan dishes. The ability to customize these items has become a significant draw for customers looking for a quick yet satisfying meal.

The convenience factor has also played a crucial role in the market’s evolution. With busy lifestyles and the desire for on-the-go eating, sandwich grills have become a favorite in offices, airports, and hospitals. The compact size and ease of cleaning have made these grills a practical choice for businesses aiming to offer fresh, hot meals to their patrons.

In Europe, the market has seen a surge in gourmet sandwiches, with an emphasis on high-quality ingredients and unique flavor combinations. The rise of artisanal food markets and the appreciation for local produce have influenced the types of sandwiches being grilled, often leading to a more sophisticated and niche market segment.

North America, on the other hand, has a more diverse market, with a strong focus on convenience and speed. The introduction of fast-casual dining concepts has led to the proliferation of sandwich grills that cater to this demographic. These grills are designed to handle high volumes while maintaining consistency in quality and speed of service.

The global pandemic has also had a significant impact on the sandwich grill market. With a heightened focus on hygiene and contactless service, grills that can easily be sanitized and maintain a clean environment have become even more popular. The shift towards takeout and delivery services has also highlighted the importance of efficient and reliable cooking equipment.

Another trend that has influenced the market is the rise of social media and influencers. The visual appeal of perfectly grilled sandwiches has made these food items a hit on platforms like Instagram and TikTok, driving demand and innovation in the industry.

In Europe and North America, the sandwich grill market has also embraced sustainability. Eco-friendly materials and energy-efficient designs are becoming standard features, as operators seek to reduce their environmental footprint while still offering high-quality food options.

The evolution of the sandwich grill market in Europe and North America is a testament to the industry’s ability to adapt to changing consumer needs and preferences. As the market continues to grow, it’s clear that the sandwich grill will remain a key player in the foodservice industry, providing delicious, convenient, and innovative meal solutions.

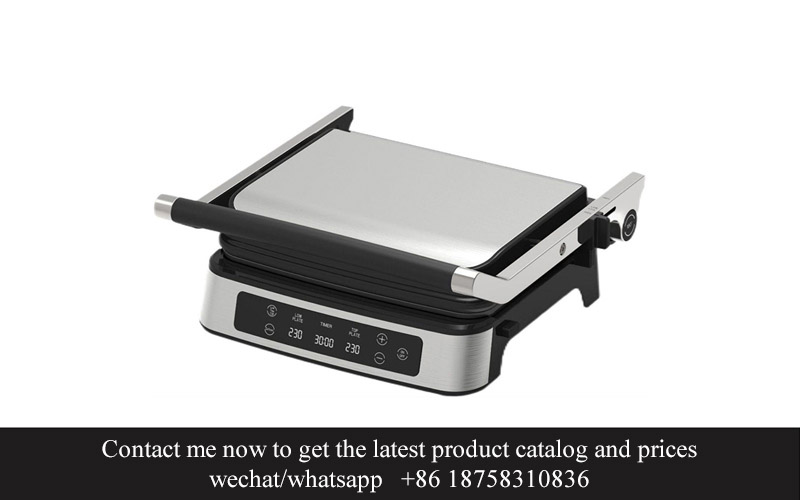

Modern sandwich grill designs have seen a remarkable evolution, with a focus on innovation that caters to both the convenience of the consumer and the efficiency of the operator. Here’s a closer look at some of the standout features that have become integral to these appliances:

Grill Technology AdvancesThe technology behind sandwich grills has progressed significantly, with innovations like dual-zone heating that allow for precise temperature control. This not only ensures that the exterior of the sandwich is perfectly toasted while the interior remains juicy, but also that different types of bread or fillings can be cooked to perfection.

User-Friendly ControlsOne of the most noticeable changes in modern sandwich grill designs is the shift towards user-friendly controls. Touchscreens and digital interfaces have replaced the old-fashioned knobs and buttons, making it easier for users to adjust settings and achieve their desired level of doneness.

Safety and Hygiene FeaturesSafety has always been a priority in kitchen appliances, and sandwich grills are no exception. Modern designs often include features like cool-touch surfaces to prevent accidental burns, non-stick coatings to simplify cleaning, and automatic shut-off mechanisms to prevent overheating.

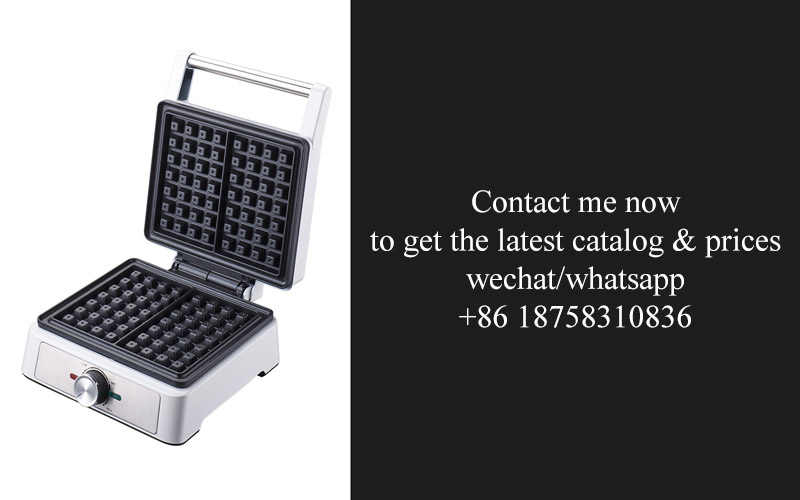

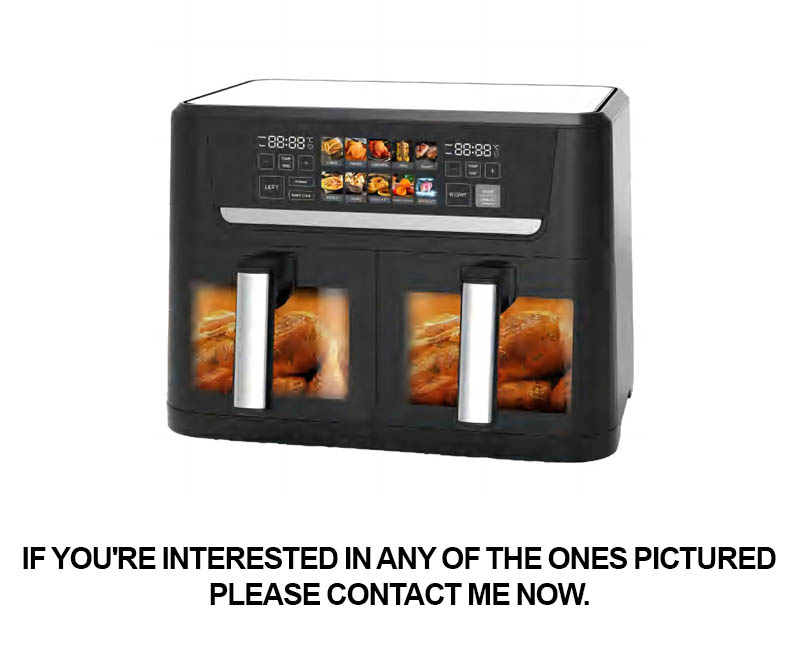

Versatility in Cooking OptionsWhile traditional sandwich grills were designed for the classic toasted sandwich, modern versions offer a range of cooking options. Some models can now grill, toast, and even sear, allowing for the preparation of a wider variety of food items like paninis, wraps, and even pizza slices.

Smart Technology IntegrationThe integration of smart technology has been a game-changer for sandwich grill designs. Grills can now be connected to smartphones or tablets, allowing users to control the cooking process remotely. This feature is particularly useful for busy cafes and restaurants that want to optimize their service without compromising on quality.

Customizable Cooking ProfilesModern sandwich grills often come with customizable cooking profiles, allowing users to save their preferred settings for different types of sandwiches. This not only saves time but also ensures consistency in the final product, whether it’s a morning rush or a busy lunch hour.

Improved Heat DistributionThe evenness of heat distribution is crucial for a great sandwich. New grill designs feature advanced heat distribution systems that eliminate hotspots, ensuring that every bite is cooked to the same level of perfection.

Eco-Friendly and Energy-EfficientAs sustainability becomes a more pressing concern, manufacturers are focusing on creating eco-friendly and energy-efficient sandwich grills. These appliances are designed to use less energy while still providing the same level of performance, which is a win for both the environment and the operator’s bottom line.

Sleek and Modern AestheticsThe aesthetic appeal of sandwich grills has also seen a transformation. Modern designs are sleek and modern, with stainless steel finishes and minimalistic designs that fit seamlessly into contemporary kitchen environments.

Ease of MaintenanceMaintenance is a crucial aspect that often goes unnoticed but is vital for the longevity of kitchen equipment. Modern sandwich grills are designed with easy maintenance in mind, featuring removable parts and non-stick surfaces that make cleaning a breeze.

Interactive Cooking DemonstrationsSome advanced models come with interactive cooking demonstrations that guide users through the process of making a perfect sandwich. This is particularly helpful for those who are new to using a sandwich grill or for training staff in a commercial setting.

In summary, the evolution of sandwich grill designs reflects a commitment to innovation, user experience, and practicality. From technological advancements to smart features and eco-friendly designs, these grills are not just cooking appliances; they are integral tools in the modern kitchen that enhance efficiency and delight consumers.

The integration of continuous operation capabilities into sandwich grill plants has revolutionized the efficiency and profitability of these establishments. Here’s how:

In the realm of sandwich preparation, time is of the essence. Continuous operation sandwich grill plants have eliminated the traditional bottlenecks associated with intermittent cooking. By allowing for a seamless flow of sandwiches through the grill, these systems have significantly reduced wait times for customers, leading to increased foot traffic and a more pleasant dining experience.

Energy efficiency has become a cornerstone of modern sandwich grill design. Continuous operation models are engineered to maintain optimal cooking temperatures with minimal energy consumption. This not only reduces utility bills but also minimizes the environmental footprint of the business. The precise control systems in these grills ensure that energy is used effectively, without waste.

The durability of continuous operation sandwich grills is unparalleled. Designed for around-the-clock use, these grills are constructed with robust materials that withstand constant heat and pressure. This longevity translates into lower maintenance costs and a longer operational life, ensuring that the investment in a continuous operation grill pays off over time.

The ability to produce a high volume of sandwiches in a short period has a direct impact on profitability. With continuous operation, sandwich shops can handle peak hours more effectively, such as lunchtime or during special events. This scalability allows businesses to maximize revenue during peak times without the need for additional staff or equipment.

Labor costs are another critical factor. Continuous operation sandwich grills reduce the need for constant supervision and frequent product checks. Operators can focus on other tasks or manage multiple stations more efficiently, leading to a more streamlined workforce. This not only saves on labor expenses but also enhances productivity.

Quality control is maintained through the consistent and uniform cooking process provided by continuous operation sandwich grills. The even distribution of heat ensures that each sandwich is cooked to perfection, reducing the risk of undercooked or overcooked products. This consistency is crucial for customer satisfaction and repeat business.

The scalability of continuous operation systems is a game-changer for businesses looking to expand. Whether it’s adding more grill units or integrating additional features like toasting or sandwich assembly lines, these systems are designed to grow with the business. This flexibility allows for future upgrades and expansions without major overhauls.

In terms of menu diversity, continuous operation grills can handle a variety of sandwich types, from classic ham and cheese to gourmet creations with multiple fillings and toppings. This versatility ensures that the menu can evolve with changing trends and customer preferences, keeping the business competitive.

Maintenance is streamlined with continuous operation sandwich grills. Regular cleaning and maintenance schedules are simplified due to the design of these grills, which allows for easy access to all components. This reduces downtime and ensures that the grill is always ready to produce high-quality sandwiches.

The integration of technology, such as digital temperature controls and smart monitoring systems, has further enhanced the efficiency of continuous operation sandwich grills. These features provide real-time data and alerts, allowing operators to make adjustments quickly and maintain optimal cooking conditions.

In conclusion, the impact of continuous operation on efficiency and profitability in the sandwich grill market is profound. From reducing wait times and energy costs to enhancing quality control and scalability, these grills have become a cornerstone of modern sandwich shop operations. The future of the industry looks bright, with continuous operation systems at the forefront of innovation and success.

The sandwich grill market in Europe and North America has witnessed a remarkable evolution over the years, driven by changing consumer preferences, technological advancements, and shifting market dynamics. From the early days of simple countertop grills to the sophisticated, commercial-grade machines now in use, the landscape has transformed significantly.

Grills have transitioned from being mere appliances to integral components of fast-casual dining experiences. The demand for convenience, health, and variety has spurred innovations in design and functionality. Here’s a closer look at some of the key developments:

This evolution in the sandwich grill market has not only been driven by consumer demands but also by the need for businesses to stay competitive. The following are some of the impacts of these changes:

As the sandwich grill market continues to evolve, it’s clear that these appliances are no longer just a means to cook sandwiches; they are integral tools that can significantly impact the efficiency and profitability of a business. The future of the market will likely see further innovations that not only cater to the evolving tastes of consumers but also address the operational and environmental challenges faced by the industry.

In the bustling heart of downtown Chicago, “GrillGuru” has become a beacon for sandwich enthusiasts. This sandwich grill plant operates 24⁄7, a testament to the continuous operation model that’s transforming the industry. Their secret? A state-of-the-art system that ensures seamless production throughout the night, with a team of skilled workers who maintain the grills and prepare ingredients in shifts.

At “BreadBusters” in New York, the continuous operation model has been in place for over a year. What sets them apart is their commitment to sustainability. The plant runs on renewable energy sources, and their grills are designed with energy-efficient technology. This not only reduces their carbon footprint but also keeps operational costs low, making their sandwiches not just delicious but also eco-friendly.

“Sandwich Station” in Los Angeles has seen a remarkable transformation with their continuous operation sandwich grill plant. What started as a small local café has expanded into a franchise with multiple locations. The key? Their ability to produce sandwiches at a high volume without compromising on quality. The plant’s automated systems ensure consistent flavor profiles, while the ability to operate around the clock has allowed them to cater to customers’ demands at any hour.

In the UK, “GrillHouse” has turned heads with their innovative approach to continuous operation. They’ve integrated advanced AI into their sandwich-making process, allowing for real-time adjustments to meet customer preferences. This has not only increased efficiency but also resulted in a personalized experience for each customer. The plant’s success lies in its ability to adapt quickly to market trends and consumer demands.

“QuickGrill” in Dallas is another prime example of how continuous operation can lead to success. Their plant operates 24 hours a day, ensuring that their sandwiches are always fresh and available. The secret to their success? A rigorous training program for their staff, who are adept at handling the high-speed production line. This dedication to their team’s skills has allowed them to maintain a high level of quality despite the relentless pace.

“SubSquad” in Miami has taken the concept of continuous operation to new heights with their mobile sandwich grill plant. They can set up in virtually any location, from festivals to corporate events, providing fresh, hot sandwiches on the go. The flexibility of their operation has allowed them to tap into a niche market, catering to those who value convenience and quality.

“GrillBros” in San Francisco has embraced the continuous operation model with a focus on health and wellness. Their plant is equipped with grills that can cook a variety of healthy options, from vegetarian to vegan sandwiches. The plant’s ability to produce these options around the clock has made them a favorite among health-conscious consumers.

“SandwichShack” in Atlanta has found a unique way to leverage continuous operation by offering a subscription service. Customers can sign up for a weekly delivery of their favorite sandwiches, ensuring a constant supply of fresh, homemade meals. This model has not only increased customer loyalty but also optimized the plant’s production schedule.

In Boston, “GrillGourmet” has taken the continuous operation concept to the next level by offering a premium experience. Their plant is staffed by chefs who handcraft each sandwich, ensuring the highest quality. Despite the continuous operation, the attention to detail and commitment to quality have kept their sandwiches in high demand.

These case studies highlight the versatility and potential of continuous operation sandwich grill plants. From adapting to different markets and consumer preferences to embracing technology and sustainability, these plants are not just cooking up success but also setting the pace for the future of the sandwich industry.

In the competitive landscape of the sandwich grill industry, several challenges face manufacturers and operators alike. These hurdles range from technological advancements to consumer demands, and navigating them requires innovative solutions.

Grill Performance and Durability IssuesSandwich grills, especially those designed for continuous operation, often encounter performance and durability challenges. High-heat exposure and constant use can lead to wear and tear, potentially reducing the lifespan of the equipment. To combat this, manufacturers have been investing in robust materials and advanced heat distribution systems. For instance, the use of stainless steel alloys that can withstand extreme temperatures and corrosion is becoming more prevalent.

Energy Efficiency ConcernsOne of the biggest challenges in the industry is the energy consumption of sandwich grills. Continuous operation can lead to significant energy costs, which can be a substantial burden on businesses. To address this, there’s been a surge in the development of energy-efficient grill models. Features like smart temperature control and insulation improvements are not only reducing energy bills but also minimizing the carbon footprint.

Consumer Safety and HygieneMaintaining high safety and hygiene standards is crucial in the foodservice industry. Continuous operation sandwich grill plants must adhere to strict regulations to prevent cross-contamination and ensure food safety. Challenges include keeping surfaces clean, preventing food particles from sticking, and ensuring that the grill can be quickly sanitized between uses. Solutions involve the design of easy-to-clean surfaces, the inclusion of automatic cleaning functions, and the use of non-stick coatings.

Customization and FlexibilityCustomers today expect a high degree of customization in their food options. Sandwich grill plants must be able to adapt to a variety of recipes and cooking styles. This flexibility can be a challenge, as it requires grills that can handle different types of bread, meats, and fillings without compromising quality. The industry response has been the creation of modular grill systems that can be customized with various attachments and accessories.

Compliance with RegulationsNavigating the complex web of health, safety, and environmental regulations is a constant challenge. Continuous operation sandwich grill plants must stay updated with the latest standards and ensure that their equipment meets or exceeds these requirements. Compliance solutions include investing in certifications, working closely with regulatory bodies, and implementing systems that can track and document compliance efforts.

Maintenance and ServiceRegular maintenance is essential for the longevity and performance of sandwich grill equipment. However, the continuous operation nature of these grills means that maintenance schedules must be meticulously planned to minimize downtime. The industry has responded with predictive maintenance technologies that use sensors and software to predict when maintenance is needed, thereby reducing unexpected breakdowns.

Economic Fluctuations and Market VolatilityEconomic changes can impact the demand for sandwich products, leading to market volatility. Operators of continuous operation sandwich grill plants must be agile, adjusting production and inventory levels to match consumer demand. Solutions include flexible supply chains, just-in-time manufacturing practices, and financial strategies that can withstand market fluctuations.

Training and StaffingThe human element is critical in the success of any business, particularly in the foodservice industry. Continuous operation requires skilled staff who are trained to use the equipment efficiently and safely. The industry has addressed this challenge by offering comprehensive training programs, ensuring that staff are up-to-date with the latest equipment and safety protocols.

Innovation in Design and FunctionalityFinally, the continuous operation sandwich grill industry faces the ongoing challenge of innovation. Staying ahead of the curve means constantly improving design and functionality. Solutions here include collaborative design processes with chefs and foodservice professionals, investing in research and development, and embracing new technologies that can enhance the cooking experience and customer satisfaction.

In the ever-evolving landscape of sandwich grill technology, several factors are shaping the future of this industry. From advancements in materials to the integration of smart features, the future of sandwich grills is poised to revolutionize the way we cook and enjoy our meals.

The integration of smart technology is becoming increasingly prevalent. Grills that can be controlled via smartphone apps are not just a novelty; they’re becoming a standard feature. These smart grills offer precise temperature control, timers, and even alerts for when the perfect sandwich is ready. The ability to monitor and adjust cooking parameters remotely is not only convenient but also ensures consistency and quality, which are key factors in maintaining customer satisfaction.

Sustainability is another driving force. As consumers become more environmentally conscious, the demand for energy-efficient appliances is on the rise. Modern sandwich grill designs are focusing on reducing energy consumption through improved insulation and more efficient heating elements. This shift not only aligns with global sustainability goals but also offers long-term cost savings for businesses.

Customization is key in the food industry, and sandwich grills are no exception. New designs are incorporating modular components that allow for easy swapping of parts, such as different grill plates for various types of sandwiches or toppings. This flexibility means that restaurants can quickly adapt to changing menu items or special dietary requirements without a complete overhaul of their equipment.

The rise of health-conscious eating habits is also influencing grill technology. With an increased focus on clean eating and whole food preparation, sandwich grills are being designed with healthier cooking options in mind. Non-stick surfaces, ceramic coatings, and even induction heating are being used to reduce the need for oil and fat, promoting healthier cooking methods.

Safety is paramount in any kitchen, and the future of sandwich grill technology is no different. New features like automatic shut-off mechanisms, child safety locks, and anti-overheating sensors are becoming standard. These innovations not only protect users but also ensure compliance with stringent health and safety regulations.

Innovation in materials is also a significant trend. The use of high-quality, durable materials like stainless steel and advanced ceramics is not just for longevity; it’s also about maintaining a clean and hygienic cooking environment. These materials are resistant to corrosion and are easier to clean, which is crucial in a commercial kitchen setting.

The future of sandwich grill technology also involves the integration of IoT (Internet of Things) capabilities. Grills that can communicate with other kitchen appliances and systems can optimize energy use, predict maintenance needs, and even reorder supplies when inventory is low. This level of connectivity can streamline kitchen operations and reduce downtime.

As the world becomes more connected, the globalization of food trends is also impacting the sandwich grill industry. The popularity of international cuisine has led to a demand for grills that can handle a variety of cooking styles, from the smoky flavors of barbecue to the delicate taste of Japanese yakitori. This diversity requires versatile and adaptable grill designs that can cater to a global palate.

Lastly, the future of sandwich grill technology is about accessibility. As the industry continues to innovate, the cost of high-tech grills is expected to decrease, making them more accessible to small businesses and home chefs alike. This democratization of technology means that anyone can enjoy the benefits of advanced cooking appliances, regardless of their budget.

In conclusion, the future of sandwich grill technology is bright and filled with possibilities. From smart features and sustainability to customization and safety, the industry is on the cusp of a new era where innovation meets practicality, creating a more efficient, healthier, and enjoyable dining experience.

In the competitive landscape of the food service industry, continuous operation sandwich grill plants are revolutionizing the way we think about fast, fresh, and delicious sandwiches. These specialized facilities are not just redefining the production process but also setting new standards for efficiency, scalability, and customer satisfaction.

The integration of advanced technology and streamlined operations allows these plants to churn out high-quality sandwiches at a rapid pace, ensuring a steady supply for busy cafes, restaurants, and food courts. This transformation is marked by several key aspects:

Grill Automation and PrecisionModern sandwich grill plants employ automated systems that precisely control the cooking process. Sensors and programmable logic controllers (PLCs) ensure that each sandwich is grilled to perfection, with consistent temperatures and cooking times. This level of automation not only reduces the margin for error but also allows for the production of a wide variety of sandwich types, from classic burgers to gourmet creations.

Flexible Production LinesContinuous operation doesn’t mean a one-size-fits-all approach. These plants are designed with modular production lines that can be easily reconfigured to accommodate different menu items and volume fluctuations. This flexibility is crucial for businesses that want to adapt quickly to changing consumer preferences and seasonal demands.

Quality Control and HygieneMaintaining high standards of food safety and hygiene is paramount in the food industry. Continuous operation sandwich grill plants are built with these principles in mind, featuring stainless steel surfaces, automated cleaning systems, and rigorous quality checks at every stage of the production process. This commitment to cleanliness not only ensures customer safety but also enhances the reputation of the brands that operate these facilities.

Reduced Labor CostsWhile the initial investment in automated equipment can be significant, the long-term benefits are substantial. Continuous operation sandwich grill plants require fewer staff members to manage the production line, thanks to the automation of many tasks. This not only cuts down on labor costs but also allows for a more focused workforce, which can be trained to handle more complex roles like customer service and inventory management.

Enhanced Customer ExperienceThe speed and consistency of sandwiches produced by continuous operation plants directly impact the customer experience. With shorter wait times and a reliable supply of fresh sandwiches, customers are more likely to return to these establishments. Additionally, the ability to offer a variety of sandwiches tailored to individual tastes has expanded the appeal of these plants to a broader demographic.

Supply Chain IntegrationContinuous operation sandwich grill plants are often integrated into larger supply chains, allowing for efficient distribution of raw materials and finished products. This integration ensures that the plants have a steady supply of high-quality ingredients and can quickly respond to any disruptions in the supply chain.

Sustainability and Energy EfficiencyAs environmental concerns grow, continuous operation sandwich grill plants are increasingly focusing on sustainability. Advanced cooking technologies and energy-efficient systems are being implemented to reduce the carbon footprint and operational costs. This shift towards sustainability not only benefits the planet but also appeals to eco-conscious consumers.

Innovation in Packaging and DeliveryTo keep up with the demands of a mobile society, these plants are investing in innovative packaging solutions that maintain the freshness and quality of sandwiches during transportation. Additionally, some are exploring delivery options that use electric vehicles and smart routing systems to minimize environmental impact and delivery times.

The continuous operation sandwich grill plant model is reshaping the food service industry. By combining automation, flexibility, and a commitment to quality, these facilities are not just changing the game—they’re setting the stage for the future of fast food production. As technology continues to evolve, we can expect to see even more innovative solutions that will further enhance efficiency, profitability, and customer satisfaction in this dynamic sector.

The continuous operation revolution in the kitchen appliances sector is reshaping the way we think about efficiency, convenience, and culinary experiences. This shift is particularly evident in the sandwich grill market, where innovation is not just a buzzword but a driving force behind new and improved technologies. As we delve into the impact of this revolution, it’s clear that the game is changing, and with it, the way we approach foodservice operations.

The rise of automated sandwich grill systems has brought about a transformation in the way these grills are used. Once a manual process requiring constant attention and adjustments, these new systems are designed to operate seamlessly, reducing the need for human intervention. This shift has allowed for a more consistent and hygienic preparation of sandwiches, burgers, and other grilled foods.

These advanced grill plants are equipped with features that ensure a continuous flow of food items through the cooking process. Sensors and automated controls adjust heat levels and cooking times based on the type of sandwich being prepared, ensuring that each product is cooked to perfection. This not only saves time but also minimizes waste, as overcooked or undercooked items are a thing of the past.

The integration of smart technology has been a game-changer. Grills can now be connected to central systems that monitor performance and provide real-time data. This allows for predictive maintenance, reducing downtime and extending the lifespan of the equipment. Operators can track usage patterns, identify peak times, and optimize their workflows accordingly.

In terms of profitability, the efficiency gains from continuous operation are significant. With less labor required to manage the grills, businesses can allocate resources to other areas of their operations. The reduction in waste also translates to cost savings, as there is less need for discarded products. Moreover, the consistency in quality and speed of service can lead to increased customer satisfaction and repeat business.

Market trends and consumer preferences are also evolving in tandem with these technological advancements. Consumers are looking for convenience, speed, and quality in their food choices, and continuous operation sandwich grill plants are perfectly positioned to meet these demands. The ability to serve a high volume of customers in a short amount of time is a compelling feature for fast-casual restaurants, cafes, and even high-end foodservice establishments.

Case studies of successful continuous operation sandwich grill plants show a clear pattern of improved efficiency and profitability. For instance, a popular fast-food chain implemented a state-of-the-art grill system that increased their throughput by 30%. Not only did this lead to shorter wait times for customers, but it also resulted in a 15% reduction in labor costs.

However, challenges remain in the industry. The initial investment for these advanced systems can be steep, and not all businesses have the capital to make the switch. Additionally, the learning curve for staff can be steep, requiring training to operate the new technology effectively. Despite these challenges, many businesses are finding creative solutions to integrate continuous operation into their existing workflows.

One such solution is the implementation of modular designs that allow for scalability. Businesses can start with a smaller system and expand as their needs grow. This approach minimizes the financial risk and ensures that the technology can grow alongside the business.

Looking ahead, the future of sandwich grill technology is bright. We can expect to see further advancements in automation and smart technology. Grills may soon be capable of predictive maintenance, self-cleaning functions, and even the ability to learn and adapt to different food types and cooking preferences.

The continuous operation revolution is not just changing the game; it’s setting the stage for a new era of culinary innovation. As businesses embrace this technology, they open themselves up to new opportunities for growth and success. The kitchen appliances sector is poised for a dynamic future, where the focus is not just on cooking but on creating an entire experience that satisfies the modern consumer’s demand for speed, quality, and convenience.