within the hastily evolving foodservice marketplace, business waffle maker factories are experiencing a surge in innovation, driven by using the growing demand for health-conscious and customized delicacies. As purchasers are trying to find handy and numerous breakfast options, industrial waffle irons have become increasingly popular in towns. those factories are focusing on performance and fine, introducing smart manipulate technology, electricity-saving designs, and multi-purposeful skills to fulfill the wishes of modern city diners. With a strong uncooked cloth supply chain and a global marketplace ability, industrial waffle maker factories are poised for sustainable growth and brand internationalization.

The Ningbo kitchen equipment dealer has seen excellent fulfillment, surpassing 10,000 devices sold month-to-month, way to its modern merchandise and strategic marketplace technique. With a keen consciousness on assembly the evolving wishes of clients, Ningbo’s supplier has delivered smart and

kitchen appliances, including a microwave oven with smart cooking steering and far flung control, and strength-efficient variety hoods. via unique product design, effective advertising channels, strong after-sales provider, and continuous technological advancements, the supplier has established itself as a pacesetter inside the enterprise, using boom and innovation inside the kitchen appliance market.

in the swiftly evolving kitchen equipment enterprise, product innovation and marketplace alignment are critical for corporate increase. The Donghua place’s OEM factories, a key production hub, have visible big improvements, which include massive industrial clusters, increasing production scales, and stronger technological capabilities. marketplace trends indicate a shift closer to intelligence, strength efficiency, customization, and health and protection in kitchen appliances. progressive designs, driven with the aid of clever era and person revel in, are critical, and the MOQ 500 method allows for flexible small-batch manufacturing. these elements are important for the kitchen appliance industry’s improvement in the cutting-edge metropolis landscape.

CE-certified air fryer OEM manufacturers are driving the worldwide market’s fast growth due to their cognizance on health-aware cooking. With their low-fats, healthful features, these appliances follow strict eu safety requirements, making them popular global. As purchasers more and more prefer low-oil cooking methods, OEMs are diversifying their product strains, introducing innovative designs, and expanding functionalities like grilling and baking. Technological improvements in smart controls and electricity performance are improving consumer enjoy and marketplace competitiveness. moreover, environmental worries are main OEMs to use

substances, propelling sustainable market improvement.

An EAC compliant sandwich maker manufacturing facility inside the japanese coastal area of our u . s ., spanning 10,000 rectangular meters, focuses on generating toasters assembly ecu requirements. ready with advanced era and a dedicated R&D team, the manufacturing unit emphasizes

materials, efficient production lines, and rigorous nice manipulate. Adhering to EAC certification standards guarantees safety and environmental friendliness, making the manufacturing unit’s products aggressive inside the european market. through strategic procurement, advanced manufacturing techniques, and non-stop innovation, this manufacturing unit ensures efficiency and excellence in every thing of its equipment manufacturing.

Low minimal order amount air fryer manufacturers are capitalizing on the rising call for for healthful cooking with their progressive products. those producers are leveraging market traits consisting of customized consumption, online sales structures, and the health-aware eating trend to gain a competitive edge. by means of specializing in quick iteration, they are able to swiftly adapt to marketplace adjustments and introduce functions like clever control systems, health-pleasant substances, and multi-functional designs. With the capacity to cater to niche markets and provide custom designed answers, those manufacturers are positioning themselves for boom in each home and international markets.

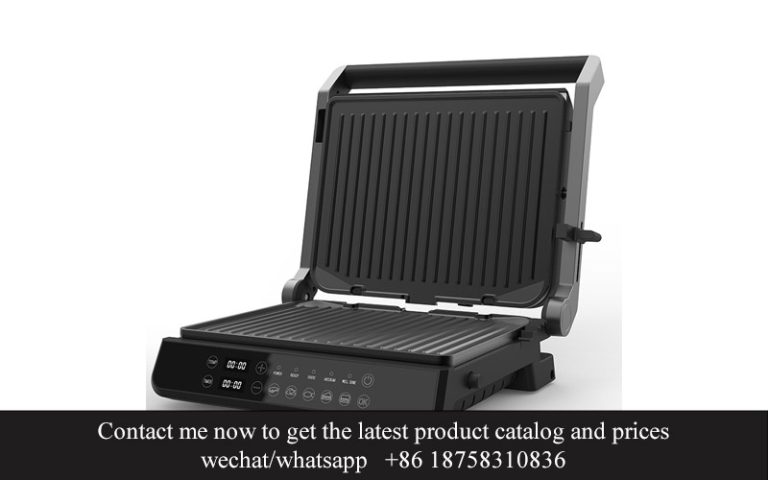

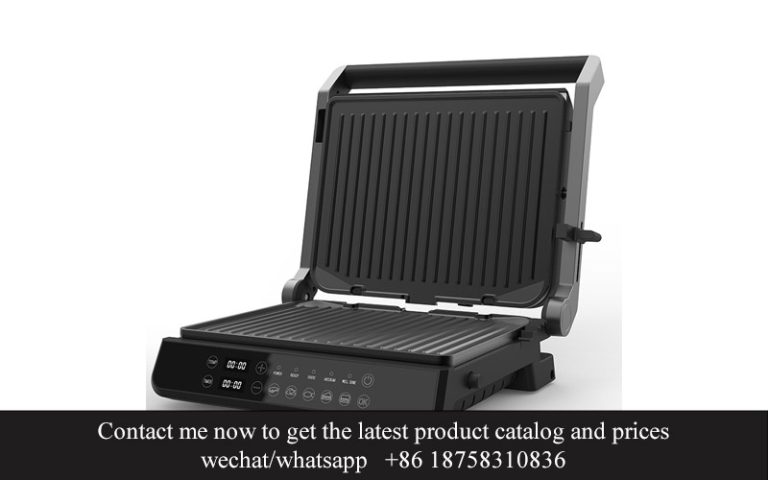

The customizable touch grill OEM marketplace is experiencing big boom due to purchaser demand for customized kitchen appliances. To reap a 30% fee discount, revolutionary answers including modular design optimization, smart production technologies, and cloth selection are being hired. This fee efficiency is critical for preserving competitiveness within the grills and call grill equipment marketplace, which is unexpectedly evolving toward shrewd, customized, and

cooking solutions.

inside the competitive kitchen appliance marketplace, businesses in metropolis, certain are leveraging excessive-extent juicer manufacturing lines for performance and rapid reaction. these automatic strains provide batch production, lowering guide exertions and growing output. The dedication to a 48-hour quoting promise sets a new industry benchmark, showcasing a focal point on client responsiveness and pleasure. via integrating smart era, prioritizing health-conscious capabilities, and embracing sustainability, those businesses are driving innovation and market management, making sure they stay ahead in the dynamic appliance commercial enterprise landscape.

The 2200W ecu Plug Air Fryer OEM is gaining recognition in the kitchen equipment market because of its electricity-efficient design and health-targeted capabilities. As clients an increasing number of call for low-fats and low-calorie cooking methods, this air fryer, with its 2200W electricity, presents an oil-loose opportunity for frying, baking, roasting, and steaming. It stands proud for its smart temperature control, protection functions, and stylish look, appealing to customers searching for both functionality and aesthetics. Its compliance with ecu voltage requirements and the CE certification guarantees its marketplace viability, making it a promising choice for brands seeking to tap into the growing demand for health-conscious cooking solutions.

the economic-grade waffle maker marketplace is witnessing fast increase, pushed via the demand for efficient and secure kitchen home equipment. those waffle irons, in particular people with NSF certification, are crucial for ensuring food protection and fine. With functions like short heating, durable substances, and clean-to-clean designs, they decorate operational efficiency in catering environments. The revolutionary generation in those appliances, including multi-functionality and strength-saving mechanisms, positions them as dependable and

solutions for business kitchens.