Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary trends are constantly evolving, the industrial panini press has quietly emerged as a game-changer in the foodservice industry. This compact yet versatile appliance has transformed the way we think about sandwiches, not just for casual eateries but also for high-end restaurants and food trucks. Let’s delve into the fascinating journey of the industrial panini press, exploring its rise from a simple home gadget to a staple in commercial kitchens worldwide.

The Bread Revolution: The Genesis of the Industrial Panini Press

In a world where culinary innovation meets convenience, the industrial panini press has emerged as a game-changer for the bread experience. Picture this: a humble slice of bread transformed into a mouthwatering, crispy delight, all thanks to a sleek, efficient machine. The journey of the industrial panini press is a testament to how technology can elevate the everyday into the extraordinary.

Once confined to the realms of home kitchens, the panini press has soared into the commercial world, becoming an indispensable tool in various industries. It’s not just about making sandwiches anymore; it’s about creating an experience that tantalizes the taste buds and satisfies the hunger for something new.

The story of the industrial panini press begins with a simple yet revolutionary idea: to merge the art of cooking with the science of efficiency. Early models were modest, often nothing more than a flat surface with a heating element. But as demand grew, so did the ingenuity of manufacturers, leading to the birth of a new era in bread preparation.

These early presses were not just about cooking; they were about speed. In a fast-paced world, the ability to quickly serve up a warm, toasted sandwich was a significant advantage. Businesses from cafes to food trucks embraced this technology, recognizing its potential to enhance their offerings and keep customers coming back for more.

As the panini press evolved, so did its capabilities. The once basic heating element was replaced with sophisticated heating systems that could achieve precise temperatures, ensuring that each piece of bread was cooked to perfection. The design also became more user-friendly, with features like adjustable heat settings and non-stick surfaces that made the cooking process smoother and more enjoyable.

But it wasn’t just about the technology; it was about the experience. The industrial panini press became a symbol of innovation, a tool that could turn a simple slice of bread into a gourmet treat. It allowed chefs and bakers to experiment with different ingredients, creating unique and flavorful sandwiches that could be customized to suit individual tastes.

The rise of the industrial panini press also coincided with a shift in consumer preferences. People were no longer satisfied with the same old sandwiches; they wanted variety and quality. The press provided this, allowing for the inclusion of fillings like avocado, grilled vegetables, and even gourmet meats, turning a sandwich into a meal.

As the market expanded, so did the variety of industrial panini presses. There were models designed for high-volume use in restaurants and cafes, capable of cooking multiple sandwiches at once. There were also compact models perfect for food trucks and smaller establishments. Each design catered to a specific need, ensuring that no matter the scale of operation, there was a panini press that could meet the demands.

The industrial panini press also played a role in the rise of street food culture. Food trucks and pop-up restaurants could now offer a variety of sandwiches with ease, thanks to the portability and efficiency of these machines. It was a democratization of food, where anyone could serve up a high-quality sandwich without the need for a traditional kitchen setup.

In the world of foodservice, the industrial panini press has become a staple. It’s not just a tool for making sandwiches; it’s a symbol of innovation and the pursuit of culinary excellence. Chefs and bakers alike have embraced this technology, using it to push the boundaries of what a sandwich can be.

Today, the industrial panini press stands as a testament to human ingenuity and the never-ending quest for better, faster, and more delicious food. It’s a reminder that even the simplest of ingredients can be transformed into something extraordinary with the right tools and a bit of creativity. The birth of the industrial panini press has indeed revolutionized the bread experience, forever changing the way we think about sandwiches and the foodservice industry.

The humble panini press, once a staple in home kitchens for crafting the perfect sandwich, has now transformed into a versatile and powerful tool embraced by the food service industry. This evolution from domestic to commercial use has not only expanded the horizons of what a panini press can do but has also spurred a significant growth in the market.

The first significant leap came with the introduction of countertop models designed for small to medium-sized restaurants and cafes. These compact yet efficient appliances quickly gained popularity due to their ease of use and the consistency they provided in cooking sandwiches to perfection. The market for these countertop panini presses saw a surge, as restaurateurs recognized their ability to enhance the customer experience by offering freshly toasted paninis as a quick, affordable, and appealing menu item.

As demand grew, manufacturers responded with more sophisticated models, including those with adjustable heat settings, non-stick surfaces, and programmable temperatures. This level of customization allowed operators to cater to diverse tastes and preferences, from classic ham and cheese to gourmet offerings with unique flavor profiles.

The next stage in the panini press market’s growth was marked by the introduction of larger, industrial-grade units. These robust machines were tailored for high-volume environments, such as stadiums, amusement parks, and fast-food chains. The ability to toast and sandwich a large number of bread items per hour made industrial panini presses a must-have for venues where quick service is a priority.

The commercial success of industrial panini presses also led to innovations in materials and design. Sturdy, durable construction became standard, ensuring that the machines could withstand the rigors of continuous use. Moreover, the introduction of removable cooking plates simplified maintenance and cleaning, a crucial factor in a busy kitchen setting.

Another key factor in the market’s expansion was the rise of health consciousness among consumers. The popularity of fresh, unprocessed foods coincided with the rise of the panini press, as it allowed restaurants to offer a healthier alternative to fried snacks and fast-food options. The market saw an influx of models designed for cooking not just bread, but also wraps, wraps, and other handheld meals that aligned with this dietary shift.

Technology also played a pivotal role in the growth of the panini press market. Smart features began to appear, including digital temperature controls, timers, and even Bluetooth connectivity for remote monitoring and programming. These advancements made it possible for operators to manage multiple presses with precision, ensuring consistency across their operations.

The global nature of the foodservice industry also contributed to the panini press market’s growth. As culinary trends from around the world influenced local menus, the demand for panini presses increased to accommodate these international flavors. From Italian-style sandwiches to Japanese-inspired yakitori, the panini press became a versatile tool for creating a diverse range of dishes.

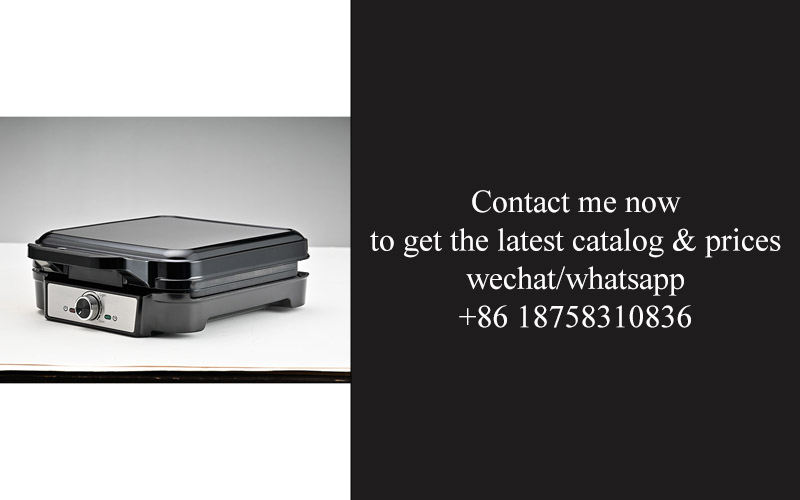

Furthermore, the rise of food trucks and mobile catering services added another layer to the panini press market. These portable, battery-powered models allowed operators to offer paninis on the go, making them an essential piece of equipment for businesses looking to reach customers in new and innovative ways.

As the market has matured, partnerships between panini press manufacturers and foodservice professionals have become more common. Collaborative efforts have led to the development of specialized models that cater to specific needs, such as those designed for use in gluten-free kitchens or those equipped with advanced safety features.

In conclusion, the journey of the panini press from a simple kitchen gadget to a staple in the foodservice industry has been marked by innovation, market adaptation, and consumer demand. The growth of the panini press market reflects a dynamic industry that is constantly evolving to meet the changing needs of both operators and diners.

The landscape of industrial panini presses has been transformed by a surge of innovative designs that cater to both functionality and aesthetics. Here’s a closer look at the latest trends reshaping the industry:

In recent years, the industrial panini press market has seen a significant shift towards compact and portable models. These units are designed to be easily moved from one kitchen to another, making them ideal for busy cafes, food trucks, and temporary food stalls. Their sleek profiles not only save space but also enhance the overall look of the workspace.

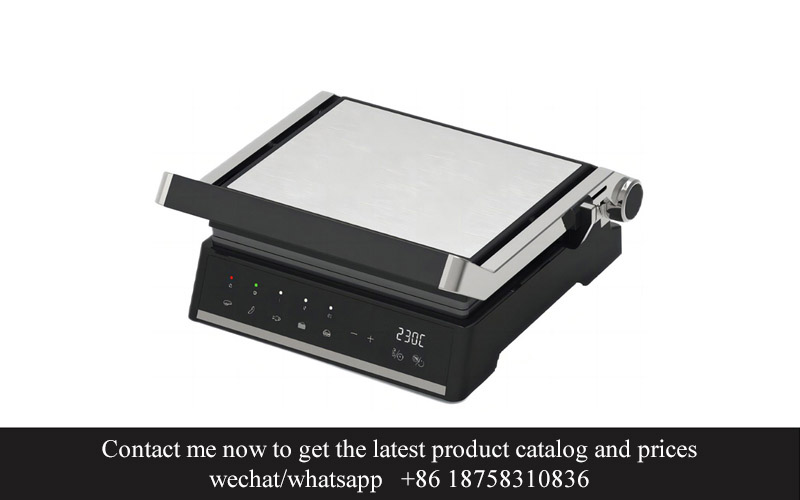

The integration of advanced technology has become a hallmark of modern industrial panini presses. Smart features like digital temperature control and programmable settings are now commonplace, allowing operators to achieve consistent results with minimal guesswork. These features not only streamline the cooking process but also ensure that each sandwich is cooked to perfection.

Eco-friendly materials have gained traction in the design of industrial panini presses. Recycled stainless steel, biodegradable plastics, and energy-efficient components are now being used to create environmentally conscious machines. This shift reflects a broader industry trend towards sustainability and a commitment to reducing the carbon footprint.

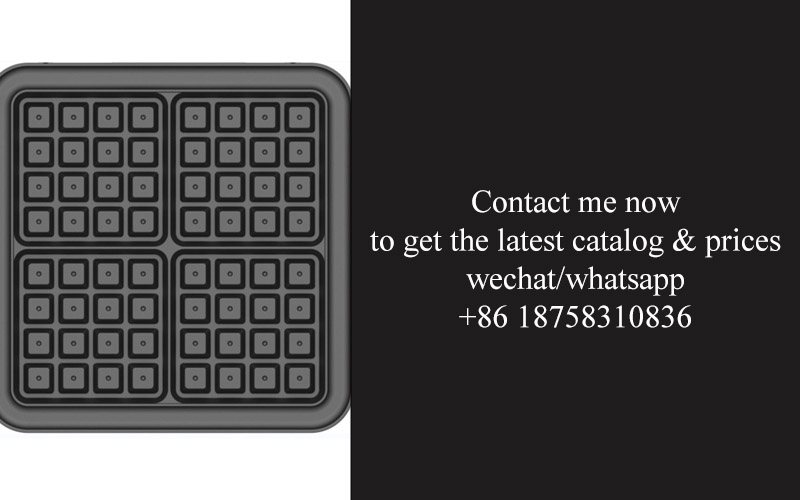

The customization of industrial panini presses has also become a significant trend. Many manufacturers offer a variety of press plates and attachments, allowing users to create a wide array of culinary delights. From gourmet paninis to stuffed sandwiches and even grilled vegetables, the versatility of these presses is unmatched. The ability to swap out plates and attachments quickly makes them a versatile tool in any kitchen.

Safety features have been beefed up in the latest industrial panini presses. Child safety locks, non-slip bases, and ergonomic handles are now standard, ensuring that operators can work safely and comfortably. The inclusion of these features is a direct response to the need for enhanced safety protocols in commercial kitchens.

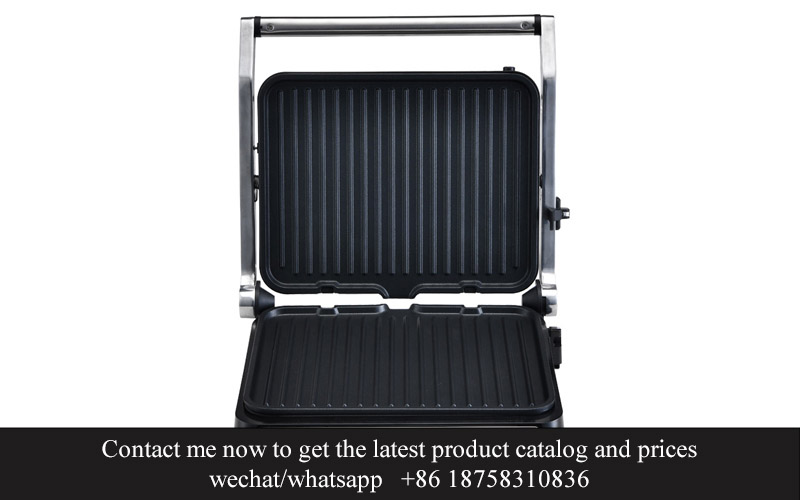

Another trend is the integration of multiple cooking surfaces. Some models now come with a grill side for searing and a panini side for pressing, doubling the functionality of the unit. This dual-sided design is particularly popular in places where a diverse menu is offered, as it allows for a variety of cooking techniques with a single appliance.

Designers are also focusing on the aesthetic appeal of industrial panini presses. The sleek, modern look of these units is a stark contrast to the traditional, bulky models of the past. The use of high-quality finishes, such as brushed stainless steel and anodized aluminum, adds a professional touch to any kitchen environment.

In terms of interface, the latest industrial panini presses feature intuitive controls and user-friendly interfaces. Touchscreens and simple button layouts have replaced the complex dials and switches of older models. This makes the machines easier to operate, even for less tech-savvy kitchen staff.

The rise of mobile catering and street food culture has spurred the development of portable industrial panini presses. These compact units are often battery-powered, allowing them to be used at outdoor events and markets without the need for a constant power source. Their lightweight construction and foldable legs make them easy to transport and set up.

Lastly, the incorporation of social media and digital marketing into the design process has led to some unique features. Some presses now come with built-in social media sharing buttons, encouraging operators to share their culinary creations with their followers. This not only boosts the operator’s brand but also serves as a marketing tool for the press manufacturer.

In summary, the evolution of the industrial panini press market is marked by a series of innovative designs that focus on compactness, technology, sustainability, customization, safety, versatility, aesthetics, user-friendliness, portability, and brand integration. These trends are shaping the future of the industry and offering new opportunities for businesses looking to enhance their food service capabilities.

In the ever-evolving landscape of kitchen appliances, consumer preferences and demand play a pivotal role in shaping market dynamics. For the industrial panini press market, understanding these factors is crucial for manufacturers and retailers alike. Here’s a closer look at the nuances of consumer preferences and demand:

Convenience and Speed: Time is a precious commodity, and consumers are increasingly seeking appliances that can deliver delicious results quickly. Industrial panini presses have stepped up to the plate, offering rapid cooking times that cater to busy lifestyles. The ability to press a sandwich within minutes has become a significant draw for customers who value efficiency.

Versatility: No longer are industrial panini presses limited to just sandwiches. Modern consumers are looking for appliances that can handle a variety of tasks. The latest models often come with adjustable heat settings and non-stick surfaces, allowing for the preparation of wraps, burgers, and even desserts. This versatility has expanded the appeal of industrial panini presses to a broader audience.

Quality and Durability: The professional-grade build of industrial panini presses has made them a favorite among consumers who demand high-quality appliances. From commercial-grade materials to sturdy construction, these presses are built to withstand the rigors of frequent use. The assurance of durability and longevity is a key factor in consumer decision-making.

Customization: Personalization is a trend that has taken hold across various industries, and kitchen appliances are no exception. Consumers are seeking appliances that can be customized to their specific needs. Features like adjustable pressure settings, multiple temperature controls, and even customizable heating elements allow users to tailor their cooking experience to their taste preferences.

Health and Wellness: As health consciousness grows, consumers are looking for appliances that can contribute to a healthier lifestyle. Industrial panini presses that offer features like adjustable browning levels and non-fat cooking options are gaining popularity. The ability to create gourmet meals with minimal oil or fat appeals to those who are mindful of their health.

Smart Technology Integration: The integration of smart technology in kitchen appliances is becoming more prevalent. Industrial panini presses that can be controlled via smartphone apps or connected to smart home systems are capturing the interest of tech-savvy consumers. The convenience of remote operation and the ability to monitor cooking progress adds a layer of sophistication to these appliances.

Eco-Friendly and Sustainable Options: Environmental concerns are at the forefront of many consumers’ minds. Industrial panini presses that are energy-efficient, made with sustainable materials, or have a focus on reducing waste are increasingly in demand. Companies that prioritize sustainability in their product development are likely to attract environmentally conscious consumers.

Brand Reputation and Trust: The reputation of the brand is a significant factor in consumer purchasing decisions. Brands that have established a strong presence in the market, known for their quality and reliability, often find that consumers are more likely to choose their products. Trust in a brand can make all the difference when it comes to market share and customer loyalty.

Cost-Effectiveness: Despite the premium price tag of some industrial panini presses, there is a growing segment of consumers who are price-sensitive. These consumers look for the best value for their money, balancing quality with affordability. Offering competitive pricing strategies and value-added features can help cater to this segment.

Social Proof and Reviews: Word-of-mouth and online reviews have a substantial impact on consumer behavior. Positive feedback from satisfied customers can significantly influence the demand for industrial panini presses. Companies that invest in customer service and encourage user-generated content are better positioned to capitalize on this dynamic.

Understanding these market dynamics and consumer preferences is essential for manufacturers and retailers in the industrial panini press market. By staying attuned to these trends, businesses can adapt their offerings to meet the evolving demands of consumers, ultimately driving growth and success.

In the world of commercial cooking, the industrial panini press has emerged as a staple for a variety of establishments, from cafes to delis. To stand out in this competitive market, these presses must offer a blend of functionality, durability, and innovation. Here are some key features to consider when selecting a top-notch industrial panini press:

Even Heat Distribution: The core of any effective panini press is its ability to evenly distribute heat across the grill plates. Look for models with precision temperature controls and non-stick surfaces that ensure every sandwich is cooked to perfection without burning or sticking.

Adjustable Temperature Settings: Different types of bread and fillings require varying levels of heat. A press with adjustable temperature settings allows for greater control, ensuring that delicate ingredients like avocado or cream cheese don’t melt away, while hearty fillings like salami and ham are cooked through.

Quick Heat-Up and Cool-Down: Time is money in the kitchen, especially during peak hours. A high-quality industrial panini press should heat up quickly and cool down rapidly, minimizing downtime and maximizing productivity.

Large Grilling Surface: The size of the press is crucial, especially in high-volume operations. A larger grilling surface can handle more sandwiches at once, reducing wait times and increasing throughput.

Robust Construction: Durability is key in a commercial setting. Look for presses made with heavy-duty materials like stainless steel, which can withstand the rigors of a busy kitchen and are easy to clean and maintain.

Safety Features: Safety should never be compromised. Features like cool-to-the-touch handles, non-slip feet, and automatic shut-off mechanisms can prevent accidents and ensure peace of mind for both staff and customers.

Ease of Cleaning: A press that is a breeze to clean can save hours of labor each week. Non-stick surfaces and removable parts that can be washed in a dishwasher are invaluable in maintaining a hygienic kitchen environment.

Customizable Options: Some industrial panini presses offer customizable features, such as adjustable pressure settings or interchangeable grill plates. These options can cater to specific menu items or customer preferences.

User-Friendly Controls: Intuitive controls are essential for busy kitchen staff. Look for presses with easy-to-read displays, simple button interfaces, and programmable settings that allow for quick adjustments without the need for constant supervision.

Brand Reputation and Warranty: When investing in an industrial panini press, consider the reputation of the brand. A well-established manufacturer with a strong warranty can provide peace of mind and support in the event of any issues.

Energy Efficiency: In today’s environmentally conscious world, energy efficiency is a significant factor. A press that consumes less power can lead to lower utility bills and a smaller carbon footprint.

Additional Functions: Some models come with additional features like adjustable height settings, allowing for the cooking of a variety of foods, not just sandwiches. This versatility can be a game-changer for businesses looking to diversify their offerings.

By focusing on these key features, you can ensure that your industrial panini press not only meets the demands of your kitchen but also enhances the overall dining experience for your customers. Remember, the right press can be a game-changer for your business, so it’s worth taking the time to find one that truly fits your needs.

In the bustling world of foodservice, the industrial panini press has become a staple in a variety of industries. From fast-casual eateries to hotels and stadiums, these versatile appliances have revolutionized how sandwiches are prepared and served. Let’s delve into some case studies showcasing successful implementations of industrial panini presses across different sectors.

In the realm of quick-service restaurants (QSRs), the panini press has become a go-to for creating delicious, on-the-go sandwiches. Case in point, a popular chain known for its wraps and sandwiches replaced their traditional grills with industrial panini presses. This switch allowed for a more even and consistent cooking process, ensuring that every sandwich was toasted to perfection. The increased efficiency also meant faster service times, which pleased both customers and staff.

For casual dining establishments, the industrial panini press has been a game-changer. One such restaurant, specializing in Italian cuisine, integrated these presses into their menu to offer a variety of panini options. The press not only added a unique twist to their menu but also enhanced the visual appeal of the sandwiches. Customers were delighted by the crispy outside and tender inside, leading to increased sales and a loyal following.

Sports venues and stadiums have also embraced the industrial panini press for their convenience and speed. During high-demand events, such as concerts or sporting games, these presses have proven to be a reliable solution for quick, hot sandwiches. A local sports stadium, for example, installed panini presses in their concession stands, providing fans with a variety of options, from classic ham and cheese to gourmet combinations. The result was a satisfied crowd and a boost in revenue for the venue.

The hospitality industry has found the industrial panini press to be a valuable asset for their breakfast and lunch offerings. A luxury hotel, renowned for its fine dining, introduced panini presses to their breakfast buffet. The press allowed them to serve a variety of sandwiches, from classic egg and cheese to smoked salmon and cream cheese, all with a professional touch. This addition to their breakfast menu was a hit among guests, who appreciated the quality and taste of the freshly prepared sandwiches.

In the healthcare sector, the industrial panini press has been a helpful tool for creating nutritious, on-the-go meals for patients. A hospital cafeteria implemented these presses to offer a range of sandwiches and wraps for their patients. The ability to quickly prepare a variety of options ensured that patients received a balanced meal, even if they were unable to dine in the cafeteria. This convenience was well-received by both patients and healthcare staff.

Educational institutions have also found the industrial panini press to be a valuable asset. A college cafeteria used these presses to offer a variety of panini options during lunch hours. The press allowed them to create a diverse menu, catering to different dietary preferences and restrictions. This flexibility ensured that all students had access to a nutritious meal, which in turn helped improve overall student satisfaction.

Lastly, in the event catering industry, the industrial panini press has been a lifesaver for event planners. A company specializing in corporate events used these presses to provide guests with a variety of sandwiches at networking events and conferences. The ability to quickly and efficiently prepare large quantities of sandwiches meant that guests could enjoy a warm, delicious meal without any delay. This efficiency was a significant factor in the success of these events.

These case studies highlight the versatility and effectiveness of the industrial panini press across various industries. From QSRs to healthcare, these appliances have proven to be a valuable addition to any kitchen, providing both convenience and quality to customers and staff alike.

In the ever-evolving world of commercial kitchen equipment, the industrial panini press has seen a remarkable transformation. This compact marvel has transitioned from a niche home appliance to a staple in various industries, redefining the way we savor bread-based treats. Let’s delve into some fascinating case studies that showcase the successful integration of the industrial panini press across different sectors.

In the fast-paced world of food service, the industrial panini press has become a go-to tool for creating mouthwatering paninis and sandwiches in minutes. One such case study involves a bustling café in the heart of a busy city. The café management was struggling to keep up with the demand for their signature sandwiches. By introducing an industrial panini press, they not only increased their production speed but also enhanced the quality and consistency of their offerings. The café’s popularity soared as customers raved about the freshly toasted, perfectly seasoned sandwiches that were ready in mere moments.

The healthcare industry has also embraced the industrial panini press for its ability to provide quick and nutritious meals for patients and staff. A hospital kitchen manager shared how the press has simplified the process of making toasted sandwiches and wraps, which are both appealing and easy to consume. The press has become a staple for creating on-the-go meals that are both healthy and satisfying, improving overall patient satisfaction and staff morale.

In the retail sector, the industrial panini press has found its way into convenience stores and markets, where it offers a unique selling proposition. A small market owner mentioned that the press has become a hit among customers looking for a quick and delicious meal option. The market now offers a variety of sandwiches, wraps, and paninis, which have become a significant revenue generator and a point of differentiation from larger competitors.

The sports and fitness industry has also seen the benefits of the industrial panini press. Gyms and fitness centers often have a café area where members can grab a nutritious meal post-workout. By integrating the press into their menu, these facilities have been able to offer a range of healthy, high-protein sandwiches that cater to the post-exercise needs of their clientele. The convenience and efficiency of the press have made it an indispensable part of their kitchen setup.

Even in the corporate world, the industrial panini press has made its mark. Many office buildings now feature micro-markets or cafes that offer a variety of quick meals. The panini press has been a popular choice for creating gourmet sandwiches for busy professionals who don’t have time to sit down for a meal. Its ease of use and versatility have made it a favorite for creating everything from classic ham and cheese to gourmet veggie options.

As we look to the future, the industrial panini press continues to evolve, offering new features and functionalities that cater to the changing needs of the market. One key trend is the integration of smart technology, with presses that can be controlled via apps or connected to kitchen management systems. This allows for precise temperature control, timers, and even the ability to program different recipes and settings.

Another area of growth is the focus on sustainability and energy efficiency. Manufacturers are exploring eco-friendly materials and energy-saving designs to reduce the environmental impact of commercial kitchen equipment. This not only aligns with the values of many consumers but also helps businesses to lower their operating costs.

The future of the industrial panini press also hinges on the demand for convenience and customization. Consumers are increasingly looking for on-the-go meals that they can tailor to their dietary preferences and restrictions. The press’s ability to create a wide range of sandwiches, from vegan to gluten-free, positions it as a versatile tool for meeting these diverse needs.

In conclusion, the industrial panini press has come a long way from its humble beginnings as a home appliance. Its successful implementations in various industries highlight its adaptability and the value it brings to foodservice operations. As technology continues to advance and consumer demands evolve, the industrial panini press is poised to remain a dynamic and essential part of the commercial kitchen landscape.