Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

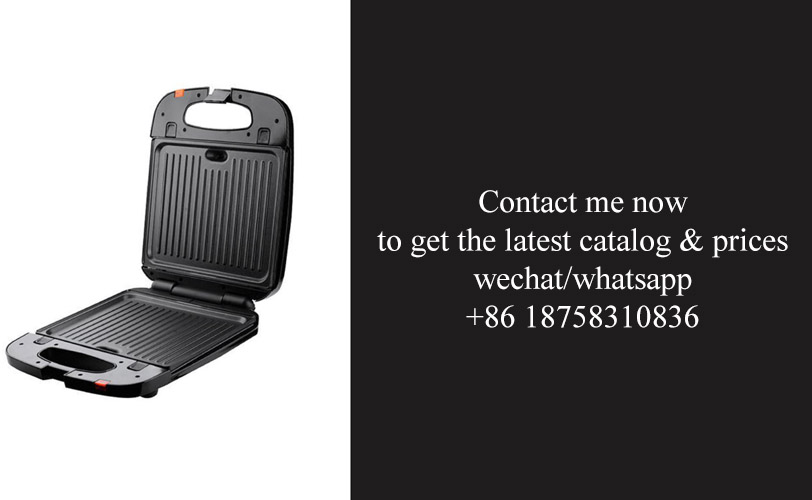

As the culinary landscape continues to evolve, one appliance that has quietly made a significant impact is the industrial waffle maker. These robust machines have become a staple in the foodservice industry, transforming the way waffles are produced and consumed. With the 220V standard as a cornerstone for many of these units, we delve into the evolution and influence of these waffle makers on the market.

The commercial kitchen scene has seen a fascinating transformation with the rise of the industrial waffle maker. Once a staple in home kitchens, these versatile appliances have now found their way into restaurants, cafes, and even catering services, becoming an essential tool for creating those perfect, crispy Belgian waffles.

Once a niche product, the industrial waffle maker market has seen exponential growth, driven by a variety of factors. For one, the demand for breakfast options has expanded beyond the traditional pancakes and eggs, with waffles emerging as a favorite due to their variety and customization potential. Chefs and restaurateurs have realized the potential of these machines to offer a unique menu item that can be a centerpiece of a breakfast or dessert menu.

The introduction of the 220V industrial waffle maker has been pivotal in this growth. These machines are designed to handle the rigors of a busy commercial kitchen, with their robust build and high power output. The 220V voltage standard, common in Europe and the United States, provides the necessary power to produce waffles quickly and efficiently, even during peak service times.

Innovations in design have also played a significant role. Modern industrial waffle makers come with non-stick surfaces that require less oil, saving both time and resources. Some models now feature digital controls that allow for precise temperature regulation, ensuring consistency in waffle texture and color. The ability to create various shapes and sizes of waffles has also become a standard feature, catering to the diverse tastes of consumers.

The market has been further fueled by the rise of the food truck and pop-up culture. These mobile food vendors often rely on compact and portable industrial waffle makers to serve their waffle-based creations to hungry crowds. The portability of these machines, combined with their durability, makes them an ideal choice for businesses that need to adapt to different locations and environments.

Data analysis has become a key factor in understanding the market’s direction. Companies are using consumer behavior data to inform their product development. For instance, research has shown that customers are increasingly looking for healthier options, leading to a surge in demand for whole grain and gluten-free waffle options. This has spurred manufacturers to develop specialized waffle makers that can accommodate these dietary preferences.

Success stories are abundant in the industrial waffle maker industry. From small cafes that have seen a significant increase in sales by offering freshly made waffles to large-scale catering companies that have integrated these machines into their mobile kitchens, the impact is undeniable. These machines have not only added a new revenue stream but have also become a popular draw for customers looking for a unique dining experience.

Looking ahead, the future of the industrial waffle maker is bright. Advancements in technology suggest that we may soon see machines with even more sophisticated features, such as integrated connectivity for remote monitoring and control. This could allow businesses to manage their waffle makers from anywhere, optimizing performance and reducing downtime.

For businesses looking to invest in an industrial waffle maker, there are several factors to consider. The size of the operation will determine the type of machine needed, whether it’s a countertop model for a small café or a larger, floor-standing unit for a bustling restaurant. Additionally, the specific features required, such as the ability to make multiple waffles at once or the inclusion of a Belgian waffle setting, should be carefully considered to ensure the best return on investment.

In conclusion, the rise of the industrial waffle maker is a testament to the evolving tastes and preferences of consumers and the innovative capabilities of the kitchen appliance industry. With its ability to enhance the menu, attract customers, and streamline operations, the industrial waffle maker has become a crucial player in the commercial kitchen landscape.

In the heart of the culinary landscape, a revolution is brewing, and it’s all thanks to the 220V standard. This voltage has become the backbone of the industrial waffle maker market, fueling innovation and efficiency in commercial kitchens worldwide.

As the demand for waffles in cafes, restaurants, and bakeries has soared, so has the need for robust, high-capacity machines. The 220V standard offers the power required to produce waffles at a commercial scale, ensuring consistency and speed that home appliances simply can’t match.

The 220V voltage provides a stable and reliable power source, which is crucial for the precision required in waffle making. These machines are designed to operate continuously, often for long hours, and the 220V standard ensures that they can handle the rigorous demands of a busy kitchen without faltering.

In the competitive world of commercial appliances, the 220V industrial waffle maker has emerged as a symbol of quality and performance. It’s not just about the power; it’s about the reliability that comes with it. These machines are built to last, with durable components that can withstand the wear and tear of a commercial setting.

The 220V standard also allows for a wider range of design possibilities. Manufacturers can incorporate advanced heating elements and control systems, ensuring that each waffle is cooked to perfection. The consistent heat distribution is key to the waffle’s texture and flavor, and the 220V voltage enables this precision.

In the past, waffle makers were often seen as a niche product, but the rise of the 220V standard has democratized access to high-quality commercial appliances. Businesses of all sizes can now afford to invest in these machines, from small cafes to large-scale catering operations.

The market for 220V industrial waffle makers has expanded beyond traditional bakeries and cafes. Food trucks, amusement parks, and even corporate events have embraced these versatile machines to offer a unique and delightful treat to their customers.

The energy efficiency of 220V waffle makers is another compelling factor. While they consume more power than their lower-voltage counterparts, the efficiency of the heating elements means that they can produce more waffles in less time, ultimately saving energy and reducing operational costs.

Innovation in the 220V industrial waffle maker sector is not just about power; it’s also about convenience. Modern machines come with features like programmable settings, non-stick surfaces, and even digital temperature controls. These advancements make the machines easier to use and maintain, further enhancing their appeal to commercial operators.

Safety is paramount in the commercial kitchen, and the 220V standard has not been overlooked. These machines are designed with safety features like automatic shut-off and overheat protection, ensuring that they can be used with peace of mind.

The global nature of the 220V standard has also made it easier for manufacturers to cater to international markets. With a consistent voltage across much of Europe and North America, these machines can be exported with minimal modifications, simplifying the supply chain and reducing costs.

The rise of the 220V industrial waffle maker is not just a trend; it’s a testament to the evolving needs of the foodservice industry. As consumers continue to seek unique and high-quality dining experiences, these machines are at the forefront, helping businesses to stand out in a crowded marketplace.

In conclusion, the 220V standard has become the driving force behind the waffle revolution. It has empowered manufacturers to create machines that are not only powerful and efficient but also user-friendly and safe. As the demand for waffles grows, so too does the importance of the 220V industrial waffle maker in the commercial kitchen landscape.

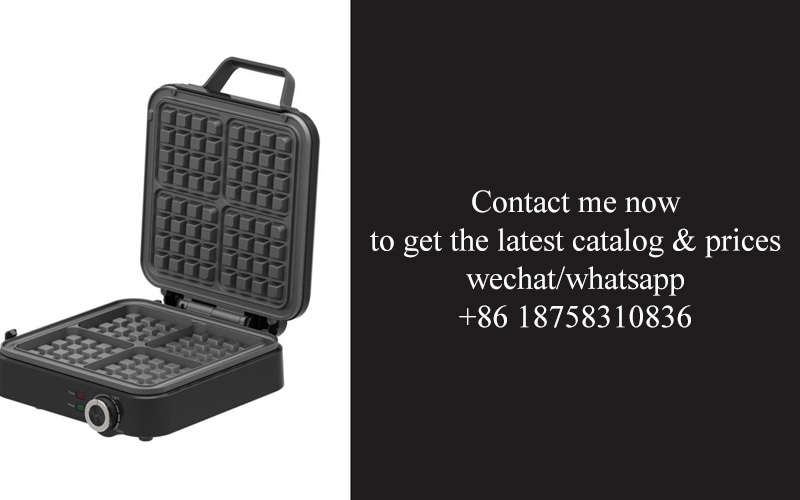

In recent years, the industrial waffle maker market has seen a wave of innovation that has transformed the way these appliances are used and valued in commercial kitchens. Here’s a glimpse into some of the most remarkable advancements:

Enhanced Heat Distribution: Modern industrial waffle makers are now equipped with advanced heating elements that ensure even heat distribution across the entire waffle iron. This technology guarantees that every waffle is cooked to perfection, with no cold spots or overcooked edges.

Non-Stick Surfaces: The days of sticky waffles are over. New industrial waffle makers feature high-quality non-stick surfaces that make it easier to release the waffles without tearing or sticking. This not only saves time but also reduces the need for excessive butter or oil, making for healthier waffles.

Programmable Settings: For those who need consistency and control, programmable settings have become a staple in the latest industrial waffle makers. Users can set specific cooking times and temperatures, ensuring that every waffle is cooked exactly to their desired level of crispiness.

Energy Efficiency: With environmental concerns at the forefront, manufacturers have focused on creating more energy-efficient waffle makers. These appliances consume less power while still providing the same high-quality results, which is a win for both the business’s bottom line and the planet.

Easy-Clean Design: Keeping commercial kitchens clean and efficient is crucial, and the latest industrial waffle makers are designed with this in mind. Features like removable plates, easy-to-clean surfaces, and drip trays make post-cooking cleanup a breeze.

Durable Construction: The robust construction of new industrial waffle makers is a testament to their longevity. From stainless steel components to heavy-duty handles, these machines are built to withstand the rigors of continuous use in busy kitchens.

Versatility: While traditionally associated with the classic Belgian waffle, today’s industrial waffle makers offer a range of patterns and shapes. From heart-shaped to rectangular, these appliances can cater to various tastes and dietary preferences.

Smart Technology Integration: Some models are now integrating smart technology, allowing for remote monitoring and control. This feature is particularly beneficial for managing operations in large-scale events or catering services where multiple waffle makers are in use.

Health and Safety Features: With health codes being stricter than ever, industrial waffle makers now come with safety features like automatic shut-off when not in use or when they reach unsafe temperatures. These features help prevent accidents and ensure compliance with regulations.

Customizable Patterns: For businesses looking to create a unique selling point, some industrial waffle makers offer the ability to customize the pattern of the waffles. This can be done by changing the mold or even using a specialized software to design custom waffle shapes.

Eco-Friendly Materials: Many manufacturers are now using eco-friendly materials in the construction of their waffle makers. From biodegradable components to sustainable wood handles, these appliances are becoming more environmentally conscious.

Portability and Compactness: Recognizing the need for versatile equipment, some models are designed to be portable and compact. This allows for easy transport and storage, making them ideal for food trucks, festivals, and pop-up restaurants.

These innovations have not only elevated the quality of waffles produced in commercial settings but have also made the process more efficient and user-friendly. As the demand for waffles continues to grow, it’s clear that the industrial waffle maker is becoming an indispensable tool in the culinary industry.

In the ever-evolving landscape of kitchen appliances, the market trends and consumer preferences for industrial waffle makers have been shifting significantly. These shifts are not only influenced by technological advancements but also by changing dietary habits and consumer lifestyles.

The surge in health-conscious eating has led to a demand for waffles made with whole grains and natural ingredients. Consumers are increasingly seeking out appliances that can cater to these preferences, pushing manufacturers to innovate in terms of recipes and machine capabilities.

One notable trend is the rise of customizable waffle makers. These devices allow users to adjust the size, shape, and depth of their waffles, as well as the texture, from crispy to fluffy. This level of personalization has become a favorite among both home chefs and commercial kitchens looking to offer unique and tailored menu items.

Smart technology integration is another key trend. Modern industrial waffle makers are now equipped with features like touch screens, digital temperature controls, and even Bluetooth connectivity for remote monitoring. This not only enhances user experience but also ensures consistent results, as the machines can be programmed to specific settings for different types of batter.

The convenience factor has also become a major driver in consumer preferences. Time-poor consumers are gravitating towards appliances that can perform multiple tasks, such as reheating or even cooking other types of breakfast items. Waffle makers that can switch between making waffles and toasting bread or bagels are becoming increasingly popular.

Another interesting trend is the focus on sustainability. As consumers become more environmentally aware, there’s a growing demand for appliances that are energy-efficient and made from recyclable materials. Manufacturers are responding by creating waffle makers that consume less power and are designed with eco-friendly practices in mind.

The rise of the foodservice industry, particularly in fast-casual and quick-service restaurants, has also influenced consumer preferences. These establishments require industrial waffle makers that can handle high volumes and are built to withstand continuous use. Features like non-stick surfaces, durable construction, and quick heat-up times are now standard in many commercial models.

Moreover, the cultural impact of waffles cannot be overlooked. From the classic Belgian Liege to the trendy waffle bowls, there’s a growing variety of waffle styles and flavors that appeal to diverse consumer tastes. This has led to an increased demand for waffle makers that can produce intricate patterns and unique shapes, catering to the whimsical side of food enthusiasts.

In terms of design, there’s a shift towards sleeker, more modern aesthetics. Consumers are drawn to appliances that not only perform well but also look good in their kitchens. The rise of minimalist designs and color options has made industrial waffle makers not just functional but also stylish additions to any commercial kitchen.

Lastly, the integration of social media and influencer culture has played a role in shaping market trends. With the rise of food blogs, Instagram posts, and YouTube videos, there’s a constant buzz around the latest kitchen gadgets and recipes. This has influenced consumers to seek out the latest and greatest in waffle making technology, often driven by what they see trending online.

As the market continues to evolve, it’s clear that consumers are seeking waffle makers that are versatile, efficient, and in tune with their health, environmental, and aesthetic values. The industrial waffle maker industry is responding with a wide array of innovations that cater to these diverse preferences, ensuring that the waffle revolution is far from over.

In today’s fast-paced business environment, data has emerged as a crucial driver of industry trends. The ability to gather, analyze, and interpret data has revolutionized how industries operate, from manufacturing to consumer goods. The role of data in shaping industry trends is undeniable, and its impact is felt across various sectors, including the industrial waffle maker market.

The Industrial Waffle Maker Market’s Data-Driven EvolutionNumbers and analytics have played a pivotal role in the evolution of the industrial waffle maker market. Sales figures, consumer behavior, and market share data have all contributed to the development of new features and design trends. For instance, the surge in demand for larger, customizable waffles has been a direct result of consumer feedback and market research.

Predictive Analytics and Future DemandPredictive analytics has become a cornerstone in forecasting future industry trends. By analyzing historical sales data and consumer preferences, manufacturers can predict which features and functionalities will be in demand. This foresight allows for the creation of products that not only meet current needs but also anticipate future consumer desires.

Customization and PersonalizationData has also influenced the rise of customization and personalization in the industrial waffle maker market. With the help of customer data, manufacturers can tailor their products to specific market segments. For example, data on dietary trends has led to the development of healthier, gluten-free, and low-carb waffle options, catering to a growing segment of health-conscious consumers.

The Impact of Social Media and Online ReviewsSocial media and online reviews have become powerful data sources for understanding consumer preferences. By monitoring hashtags, comments, and ratings, manufacturers can gain insights into what consumers love and what they don’t. This real-time data allows for quick adjustments to product design and marketing strategies.

Market Saturation and Competitive AnalysisData-driven competitive analysis helps manufacturers stay ahead in a saturated market. By analyzing competitors’ offerings, market share, and pricing strategies, companies can identify gaps in the market and develop unique selling propositions. This competitive edge is often the difference between a successful product and one that fades into obscurity.

The Shift Towards SustainabilityData has also played a role in the sustainability movement within the industrial waffle maker industry. By tracking energy consumption and material usage, manufacturers can identify areas for improvement and innovation. This shift towards sustainability is not only driven by consumer demand but also by regulatory changes and environmental concerns.

Globalization and Market ExpansionData analytics has been instrumental in the globalization of the industrial waffle maker market. Companies can use data to identify emerging markets and tailor their products to suit local preferences. The ability to understand and adapt to global trends is key to successful market expansion.

Innovation Through CollaborationCollaboration between manufacturers, suppliers, and even consumers has been fueled by data. By sharing data and insights, these stakeholders can work together to drive innovation and create products that are not only efficient but also user-friendly. This collaborative approach has led to groundbreaking advancements in technology and design.

Consumer Behavior and Technological IntegrationUnderstanding consumer behavior is vital for any industry, and the industrial waffle maker market is no exception. Data on how consumers interact with their appliances has led to the integration of smart technology, making waffle makers more intuitive and convenient. Features like touchscreens, Wi-Fi connectivity, and remote control capabilities are now becoming standard due to consumer demand.

ConclusionThe role of data in driving industry trends is multifaceted and undeniable. From shaping product development to informing marketing strategies, data has become an indispensable tool for businesses in the industrial waffle maker market and beyond. As the industry continues to evolve, the importance of leveraging data to stay ahead of the curve will only grow.

In the world of industrial waffle makers, there are several success stories that highlight the impact of innovation, strategic planning, and market understanding. Here are a few that stand out:

A. The story of WaffleWorks began with a simple observation: consumers were increasingly seeking high-quality, customizable waffles. By leveraging data analytics, the company identified a gap in the market for premium, artisanal waffles. They invested in a state-of-the-art 220V industrial waffle maker that allowed for intricate designs and precise temperature control. The result? A loyal customer base that was willing to pay a premium for their unique waffle experience.

B. WaffleWonders, a relatively new entrant in the market, made waves with their eco-friendly approach. They noticed a growing trend towards sustainability and decided to focus on energy-efficient, long-lasting waffle makers. By analyzing consumer preferences and market data, they developed a range of products that not only met the demand for sustainability but also outperformed competitors in durability. This strategic move propelled WaffleWonders to the forefront of the industry.

C. The legacy brand, Classic Creations, had been producing waffle makers for decades. They recognized the shift in consumer preferences towards healthier eating habits and the rise of gluten-free diets. Using data to predict these trends, they launched a line of gluten-free waffle makers that catered to the health-conscious market. The innovation was a hit, and it reinvigorated their brand, leading to a significant increase in sales and market share.

D. Bakers Delight, a small, family-owned business, used data analytics to understand the local market dynamics. They noticed a trend of local cafes and bakeries looking for custom-branded waffle makers to enhance their brand identity. By offering a personalized service that included custom designs and branding, Bakers Delight tapped into a niche market, creating a loyal customer base that valued their unique offerings.

E. The global brand, WaffleEmpire, expanded its reach by analyzing global market trends. They identified a surge in demand for waffle makers in emerging markets, where the Western-style breakfast was becoming popular. By adapting their product range to cater to different voltage standards and cultural preferences, WaffleEmpire successfully entered new markets and saw a significant growth in their international sales.

F. WaffleGuru, a startup with a focus on technology, leveraged data to understand consumer behavior. They noticed that consumers were not just looking for waffle makers but an entire experience. In response, they developed an app that connected users with local waffle shops, providing a platform for sharing recipes and reviews. This innovative approach not only increased sales but also fostered a community around waffles.

G. The tale of WaffleCraft, a company that started as a small local manufacturer, is a testament to the power of data-driven decision-making. They used market research to identify a trend towards healthier, whole-grain waffles. By developing a range of whole-grain waffle makers, they were able to tap into a niche market that was underserved by larger competitors. Their commitment to quality and innovation led to rapid growth and a strong reputation in the industry.

H. The story of WafflePioneers is one of resilience and adaptability. They faced stiff competition from established brands but used data to identify a gap in the market for compact, portable waffle makers. By focusing on convenience and ease of use, they developed a product that appealed to busy professionals and travelers. Their strategic use of data allowed them to pivot and stay relevant in a rapidly changing market.

These case studies illustrate how data-driven strategies can lead to success in the industrial waffle maker industry. By understanding consumer preferences, market trends, and leveraging innovative technologies, these companies have been able to carve out a niche for themselves and thrive in a competitive landscape.

In the ever-evolving world of kitchen appliances, waffle makers have transcended their humble beginnings as a weekend treat to become a staple in commercial kitchens worldwide. As we gaze into the horizon, the future of waffle makers promises a blend of innovation, sustainability, and technological advancements that will reshape the industry. Here’s a glimpse into what we can expect from the future of waffle makers.

The Integration of Smart TechnologyWaffle makers are on the cusp of becoming smart kitchen companions. Imagine a waffle maker that not only cooks your breakfast but also connects to your home automation system. It could learn your preferences, adjust cooking times and temperatures, and even order replacement parts when needed. Smart waffle makers might soon be a norm, offering personalized cooking experiences and streamlining kitchen operations.

Sustainability and Energy EfficiencyWith environmental concerns at the forefront, the future of waffle makers will likely see a significant push towards sustainability. We can anticipate the development of appliances that consume less energy, utilize renewable energy sources, and are made from recyclable materials. This shift is not just about reducing the carbon footprint; it’s about creating a product that aligns with the values of eco-conscious consumers.

Customization and PersonalizationThe future of waffle makers will likely see a surge in customization options. From adjustable browning settings to interchangeable plates that can create various waffle shapes and sizes, consumers will have the power to tailor their waffles to their exact tastes. This could also extend to the ability to program different cooking times and temperatures for different types of batter, ensuring that each waffle is cooked to perfection.

Health and Wellness FeaturesAs health and wellness become more important, waffle makers may incorporate features that cater to healthier lifestyles. This could include non-stick surfaces that require less oil, adjustable cooking temperatures to prevent burning, and even models that can cook healthier ingredients like whole grains or low-sugar alternatives. The future waffle maker could become a tool for not just delicious waffles but also for promoting healthier eating habits.

Interactive and Educational FeaturesWaffle makers might also become interactive and educational tools. Imagine a waffle maker that not only cooks your breakfast but also teaches you about the history of waffles or provides nutritional information about the ingredients you’re using. This could be especially appealing to families or culinary enthusiasts looking to enhance their breakfast experience.

Global Cuisine IntegrationThe world is becoming more connected, and this trend will likely influence the future of waffle makers. We can expect to see models that can mimic the cooking techniques of various international cuisines, allowing users to enjoy waffles with a French crepe texture or an Italian focaccia-like crispness. This would open up a whole new world of culinary exploration for waffle lovers.

Economic Shifts and AffordabilityThe future of waffle makers will also reflect economic shifts. As technology advances, the cost of manufacturing may decrease, making high-tech waffle makers more accessible to a broader market. This could lead to a democratization of kitchen technology, where even those with a tighter budget can enjoy the latest innovations.

In conclusion, the future of waffle makers is poised to be a dynamic and exciting landscape. From smart technology and sustainability to health and wellness features, the next generation of waffle makers will offer a wide array of possibilities that cater to the diverse needs and desires of consumers worldwide. Whether you’re a casual breakfast eater or a culinary adventurer, the future of waffle makers promises to be a delightful journey.

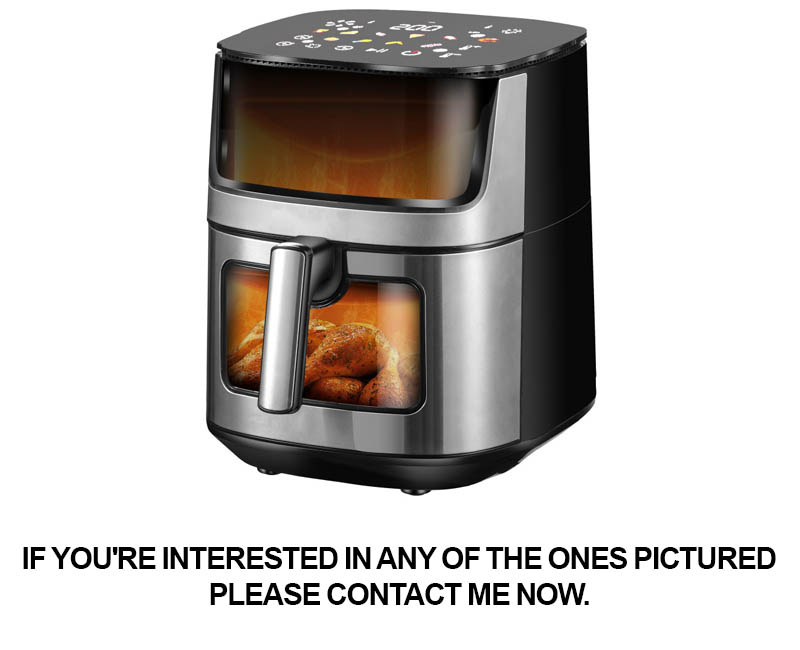

In the bustling world of commercial kitchens, selecting the right industrial waffle maker is crucial. Here are some key tips to guide you in making the perfect choice:

Consider the Size of Your OperationThe size of your waffle maker should align with the scale of your business. For a small café, a compact unit might suffice, but a bustling restaurant or bakery may require a larger, more robust model to keep up with demand.

Material MattersThe material used in the construction of the waffle maker can impact its durability and ease of cleaning. Stainless steel is a popular choice for its strength and resistance to rust, while non-stick surfaces make for quick and easy cleaning.

Look for Consistent Heat DistributionA good industrial waffle maker ensures even heat distribution across the griddle, which is essential for creating consistently golden and crispy waffles. Look for features that guarantee uniform cooking.

Think About Customization OptionsDepending on your menu, you might need a waffle maker that can produce different shapes or sizes. Some models offer interchangeable plates or the ability to adjust the thickness of the waffles, giving you more versatility.

Power and VoltageIndustrial waffle makers come in various voltage options, typically 110V or 220V. Choose the one that matches the voltage of your kitchen’s electrical system. A higher voltage can sometimes mean faster cooking times and more power, but always ensure compatibility.

Easy to Clean DesignIn a busy kitchen, a waffle maker that’s easy to clean can be a game-changer. Look for features like removable plates, non-stick surfaces, and drip trays that catch excess batter.

Safety FeaturesSafety should always be a top priority. Check for features like automatic shut-off after a certain period of inactivity, cool-touch handles, and overheat protection to prevent accidents.

User-Friendly ControlsA waffle maker with intuitive controls can save time and frustration. Digital timers, temperature settings, and simple on/off switches can make the process of making waffles more efficient.

Consider the Waffle Maker’s WeightIf you need to move your waffle maker around, consider its weight. A heavier unit may be more stable, but a lighter one can be easier to transport and store.

Warranty and Customer ServiceA good warranty can provide peace of mind, especially for a high-quality investment like an industrial waffle maker. Additionally, a manufacturer with strong customer service can be invaluable if you encounter any issues.

Energy EfficiencyIn an era of rising energy costs, it’s wise to consider the energy efficiency of your waffle maker. Some models are designed to use less energy, which can save you money in the long run.

Brand ReputationResearch the reputation of different brands within the industry. A well-established brand often means better quality and customer satisfaction.

Read ReviewsLook for reviews from other commercial kitchen professionals who have used the waffle makers you’re considering. Real-world experiences can provide valuable insights into the performance and reliability of the product.

Budget ConsiderationsSet a budget and stay within it. While it’s tempting to go for the most expensive model, sometimes a mid-range option can offer the best balance of quality and price.

LongevityThink about how long you expect to use the waffle maker. A more expensive unit may be worth the investment if it’s expected to last for many years and provide consistent results.

By carefully considering these factors, you can choose an industrial waffle maker that not only meets your current needs but also stands the test of time in your commercial kitchen.

The evolution of the 220V industrial waffle maker has undeniably left an indelible mark on the market. These appliances, once a niche product, have now become a staple in the commercial kitchen landscape. From their ability to produce consistent, high-quality waffles in bulk to their versatility in various culinary applications, the impact of these waffle makers is far-reaching. Let’s delve into the specific ways in which 220V industrial waffle makers have reshaped the market.

The demand for convenience and speed in the foodservice industry has soared, and the 220V industrial waffle maker has answered the call. Its ability to churn out waffles in a matter of minutes has made it a favorite among busy cafes, restaurants, and bakeries. The efficiency of these machines has not only improved service times but has also allowed establishments to offer a wider variety of waffle options, from classic Belgian to creative flavors and fillings.

Moreover, the reliability of 220V industrial waffle makers has become a cornerstone in the industry. These machines are built to withstand rigorous use, often boasting durable components and easy-to-clean surfaces. This durability ensures that businesses can count on their waffle makers to consistently deliver the desired results, day in and day out. The longevity of these appliances also translates to cost savings for operators, as they require less frequent replacement than their consumer-grade counterparts.

Innovation has been a driving force behind the rise of 220V industrial waffle makers. Designers have pushed the boundaries, incorporating features like adjustable temperature controls, non-stick surfaces, and programmable settings to cater to a diverse range of preferences and needs. These innovations have not only improved the user experience but have also opened up new possibilities for creative waffle designs and flavor combinations.

The market has seen a significant shift towards healthier eating habits, and 220V industrial waffle makers have adapted. Many modern models now offer healthier options, such as gluten-free, low-fat, and whole-grain waffles. This shift in consumer preferences has allowed businesses to cater to a broader audience, including those with dietary restrictions or health-conscious customers.

The environmental consciousness of consumers and businesses alike has also played a role in the success of 220V industrial waffle makers. As awareness of sustainability grows, manufacturers have responded by producing energy-efficient models that consume less power and reduce the carbon footprint. This commitment to eco-friendliness has resonated with both customers and operators, making these waffle makers an environmentally responsible choice.

The global appeal of 220V industrial waffle makers is undeniable. They have found their way into kitchens across the world, from bustling city centers to serene beachside cafes. The adaptability of these machines to various cultures and cuisines has been a key factor in their international success. Whether it’s a traditional American breakfast or a fusion dish inspired by global flavors, the 220V industrial waffle maker has become a versatile tool for chefs and bakers worldwide.

The rise of the 220V industrial waffle maker has also spurred the creation of a vibrant ecosystem of accessories and add-ons. From specialty toppings and syrups to waffle molds that create unique shapes, the market has expanded to offer a wide array of products that enhance the waffle-making experience. This ecosystem not only adds value to the waffle maker itself but also fosters innovation and creativity in the industry.

The impact of 220V industrial waffle makers on the market extends beyond the product itself. It has sparked a wave of culinary innovation, with chefs and bakers experimenting with new recipes and techniques. This innovation has, in turn, influenced the broader foodservice industry, leading to a greater emphasis on quality, variety, and customer satisfaction.

In conclusion, the 220V industrial waffle maker has become a cornerstone in the market, driving trends and shaping the future of the foodservice industry. Its efficiency, reliability, innovation, health-conscious options, environmental considerations, global appeal, accessory ecosystem, and role in culinary innovation all contribute to its significant impact. As the market continues to evolve, it’s clear that the 220V industrial waffle maker will remain a vital tool for businesses and a delight for consumers worldwide.